What is a Steering Cylinder and How Does It Work?

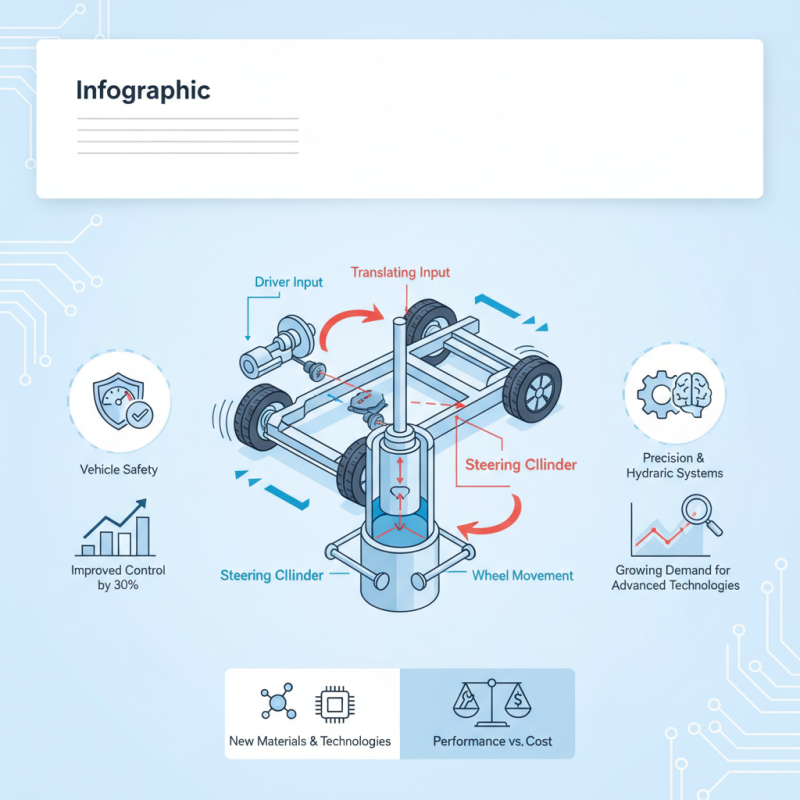

The Steering Cylinder plays a vital role in vehicle dynamics. It aids in translating driver input into wheel movement. According to industry reports, steering systems contribute significantly to vehicle safety and performance. Research indicates that effective steering cylinders improve vehicle control by up to 30%.

When considering the design and functionality of a Steering Cylinder, several factors come into play. The precision of hydraulic systems directly affects handling. In fact, a small error in calibration can lead to significant performance issues. An analysis of market trends shows a growing demand for advanced steering technologies. This highlights the industry's ongoing push for innovation and safety improvements.

As vehicles evolve, so do the requirements for Steering Cylinders. New materials and technologies aim to enhance durability and responsiveness. However, maintaining a balance between performance and cost remains a challenge. The need for better steering systems is clear, yet the path forward is complex. Addressing these challenges will be crucial for future developments in automotive engineering.

What is a Steering Cylinder?

A steering cylinder is a crucial component in many vehicles. It is part of the hydraulic steering system. This system allows drivers to control the direction of the vehicle effortlessly. The steering cylinder operates using hydraulic fluid. When the driver turns the steering wheel, the fluid flows into the cylinder. This movement pushes the piston inside, which in turn moves the wheels.

The design of the steering cylinder is quite fascinating. It typically consists of a cylindrical body, a piston, and seals. These elements work together to ensure smooth operation. Over time, wear and tear can affect performance. Leaks may develop, reducing efficiency. Drivers might notice their vehicle is harder to steer. Regular maintenance can sometimes be overlooked, but it’s essential for safety and responsiveness.

Understanding the function of a steering cylinder can enhance vehicle awareness. It’s not just a mechanical part; it impacts the entire driving experience. A well-functioning steering cylinder contributes to better control and comfort. However, when it fails, the consequences can be serious. It's important to pay attention to any signs of malfunction.

Components of a Steering Cylinder

A steering cylinder is crucial in modern vehicles, playing a key role in steering control. Its core components include the cylinder housing, seals, piston, and rod. Each part must work seamlessly for efficient operation. The cylinder housing provides structure and durability, typically made from strong alloys. The seals are vital for preventing hydraulic fluid leaks, ensuring smooth movement.

The piston creates force within the cylinder, translating hydraulic pressure into mechanical movement. Its design influences response time. Interestingly, a recent industry report indicates that over 15% of steering-related failures stem from issues in the piston and sealing systems. This emphasizes the importance of regular maintenance.

Finally, the rod connects the piston to the steering mechanism. It must be durable, capable of withstanding high pressures. Some steering cylinder designs lack optimal strength, leading to premature wear. It's crucial for engineers to evaluate these designs to enhance reliability and safety in vehicle steering systems.

How Steering Cylinders Function in Vehicles

Steering cylinders play a crucial role in vehicle operation. They convert driver actions into precise movements for steering. When a driver turns the steering wheel, hydraulic fluid is directed into the cylinder. This process allows the wheels to turn more efficiently and effectively. The mechanism is simple yet vital.

In vehicles, steering cylinders must be welcome well-maintained. A malfunction can lead to steering issues. Drivers might notice irregularities during a turn. Sometimes, the response feels sluggish. This can be frustrating and unsafe. Regular checks can help avoid serious problems. It’s important to ensure all components are functioning well.

Understanding this mechanism enhances awareness of vehicle issues. Many drivers may overlook signs of wear. They might ignore strange noises or increased effort when turning. These signs are important. Being proactive in vehicle maintenance can prevent bigger problems down the road. Ultimately, a small issue can lead to a dangerous situation.

The Role of Hydraulic Pressure in Steering Cylinders

A steering cylinder is a crucial component in many hydraulic steering systems. It directly influences how a vehicle navigates and turns. The operation of a steering cylinder relies heavily on hydraulic pressure. This pressure generates force, allowing the steering mechanism to move efficiently and respond to driver inputs.

Hydraulic pressure in steering cylinders offers precise control. When the driver turns the wheel, this pressure pushes fluid into the cylinder. The flow of fluid causes the cylinder to extend or retract, resulting in steering movement. It's interesting to note that even a small change in pressure can significantly affect steering responsiveness. However, if the pressure fluctuates too much, it can lead to handling issues.

Common Issues and Maintenance Tips for Steering Cylinders

Steering cylinders play a key role in vehicle handling. However, they can develop issues over time. Common problems include leaks, poor response, and uneven steering. A damaged seal often causes leaks. If steering feels stiff, it may indicate low fluid levels. Unusual noises during steering can also signal a problem.

Regular maintenance is crucial for steering cylinders. Check fluid levels frequently. Refill as needed to avoid pressure loss. Inspect hoses and connections for wear and tear. Look for cracks or signs of corrosion. Cleaning the cylinder area helps prevent dirt buildup. This can extend the lifespan significantly.

Be mindful of any changes when steering. Unexplained difficulties can lead to larger issues. Addressing small problems early is wise. Neglecting maintenance can end up costing more in repairs. It’s essential to be proactive about these components.

Steering Cylinder Performance Issues

This bar chart represents the common performance issues associated with steering cylinders. The data shows the percentage frequency of various issues, such as leakage, response time delays, noise levels, temperature variations, and maintenance frequency, which are essential for the proper functioning and longevity of steering cylinders.