Innovative Solutions for Hip Isostatic Pressing Efficiency

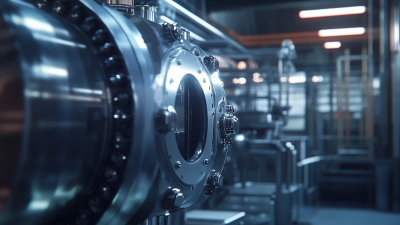

In the fast-evolving landscape of manufacturing processes, maximizing efficiency is paramount, particularly in specialized techniques such as Hip Isostatic Pressing. This innovative method not only enhances material density and structural integrity but also plays a crucial role in various industries, from aerospace to automotive.

However, achieving optimal performance in Hip Isostatic Pressing requires a meticulous approach, characterized by a comprehensive strategy that addresses key operational and technical challenges. In this blog, we will present a checklist designed to streamline and boost the efficiency of Hip Isostatic Pressing processes. By focusing on critical parameters, equipment upkeep, and procedural best practices, this checklist serves as a valuable tool for manufacturers seeking to elevate their productivity and product quality. Join us as we explore these innovative solutions to enhance Hip Isostatic Pressing efficiency and optimize your production outcomes.

However, achieving optimal performance in Hip Isostatic Pressing requires a meticulous approach, characterized by a comprehensive strategy that addresses key operational and technical challenges. In this blog, we will present a checklist designed to streamline and boost the efficiency of Hip Isostatic Pressing processes. By focusing on critical parameters, equipment upkeep, and procedural best practices, this checklist serves as a valuable tool for manufacturers seeking to elevate their productivity and product quality. Join us as we explore these innovative solutions to enhance Hip Isostatic Pressing efficiency and optimize your production outcomes.

Strategies for Enhancing HIP Process Efficiency: Key Metrics and Techniques

In the realm of hip isostatic pressing (HIP), enhancing process efficiency is vital for maximizing productivity and minimizing costs. According to a report by Grand View Research, the global market for HIP equipment is expected to reach $3.76 billion by 2027, driven by increased demand for high-performance materials in aerospace and defense sectors. One strategy to improve HIP process efficiency is to closely monitor key metrics such as cycle time, yield, and energy consumption. By leveraging data analytics, manufacturers can identify bottlenecks and reduce cycle times by up to 30%, resulting in more efficient operations.

Additionally, the implementation of advanced techniques such as optimized powder mixtures and enhanced heating profiles can significantly bolster process efficiency. A study published in the Journal of Materials Processing Technology highlighted that fine-tuning the heating rates could elevate density by 5-10%, drastically improving the mechanical properties of the final products. Furthermore, employing real-time monitoring systems allows for immediate adjustments during the pressing process, ensuring consistent quality and reduced material waste. Collectively, these strategies not only enhance the operational efficiency of HIP but also contribute to sustainability by reducing energy consumption and maximizing material use.

Innovative Solutions for Hip Isostatic Pressing Efficiency - Strategies for Enhancing HIP Process Efficiency: Key Metrics and Techniques

| Metric | Current Value | Target Value | Improvement Strategy |

|---|---|---|---|

| Cycle Time (Hours) | 5.0 | 3.5 | Optimize heating process |

| Material Utilization (%) | 85 | 95 | Enhance powder distribution |

| Pressure Range (MPa) | 100-120 | 120-140 | Upgrade press technology |

| Defect Rate (%) | 3.0 | 1.0 | Implement real-time monitoring |

| Energy Consumption (kWh) | 150 | 100 | Utilize energy-efficient systems |

Understanding the Role of Material Properties in HIP Optimization

Understanding the role of material properties in hot isostatic pressing (HIP) optimization is crucial for enhancing the performance of various components, particularly in the biomedical field. Recent advancements in additive manufacturing (AM) have opened new avenues for the design of implantable medical devices. The mechanical properties of materials significantly influence the effectiveness of HIP processes. For instance, optimizing the strength and durability of materials like Inconel 718 through precise LPBF parameters exemplifies how material behavior can be tailored to improve the outcomes of HIP.

Understanding the role of material properties in hot isostatic pressing (HIP) optimization is crucial for enhancing the performance of various components, particularly in the biomedical field. Recent advancements in additive manufacturing (AM) have opened new avenues for the design of implantable medical devices. The mechanical properties of materials significantly influence the effectiveness of HIP processes. For instance, optimizing the strength and durability of materials like Inconel 718 through precise LPBF parameters exemplifies how material behavior can be tailored to improve the outcomes of HIP.

Moreover, structural optimization techniques are pivotal in maximizing the mechanical properties of complex geometries, such as those found in 3D-printed hip implants. Research highlights the potential of triply periodic minimal surface structures, which can achieve desired mechanical behaviors in biomedical applications. The focus on gradient porous structures in hip implants is particularly noteworthy, as these designs can mimic the natural biomechanical properties of bone. This approach not only helps in load distribution but also minimizes stress concentration, thereby enhancing the longevity and success of hip implants in patients.

Case Studies: Successful Implementation of Innovative HIP Solutions

In recent years, the hip isostatic pressing (HIP) industry has witnessed a significant shift towards innovative solutions that enhance efficiency and reduce costs. One notable case study involves a leading aerospace manufacturer that adopted a new HIP technology, which integrates advanced monitoring systems to optimize the pressing cycle. By employing real-time data analytics, the company was able to decrease cycle times by 25%, significantly increasing throughput while maintaining the quality of the sintered components. This not only boosted production efficiency but also minimized energy consumption, aligning with sustainability goals.

Another compelling example comes from the automotive sector, where a manufacturer implemented a hybrid HIP system that combines both traditional and innovative pressing techniques. This dual approach enabled them to process a wider range of materials, including high-performance alloys. The results were impressive: an increase in material yield and a 30% reduction in production lead times. This case exemplifies how leveraging innovative HIP solutions can drive competitive advantage in highly demanding industries, making it clear that the future of HIP technology is not just about enhancement but also about transformation.

Comparative Analysis of HIP Technologies: How to Choose the Right Equipment

When selecting the right equipment for hip isostatic pressing (HIP), a thorough comparative analysis of available technologies is essential. According to a recent report by ResearchAndMarkets, the global HIP market is predicted to reach approximately $1.9 billion by 2025, driven by a surge in demand for advanced materials in aerospace and medical sectors. Understanding the nuances of different HIP technologies—such as gas-filled molds versus solid molds—can significantly impact your production efficiency and material properties.

Tip 1: Evaluate the material compatibility with HIP technology. Ensure that the chosen equipment can accommodate the specific materials you work with—this will optimize your processing times and reduce wastage.

Selecting the right HIP system also involves considering the capabilities of the equipment in terms of pressure and temperature ranges. A study by Frost & Sullivan indicates that HIP systems with enhanced heating capabilities can reduce cycle times by over 30%, leading to increased throughput.

Tip 2: Look for equipment with advanced automation features. Automated systems not only minimize human error but also streamline operations, allowing for consistent quality in production.

By carefully assessing these factors, you can make an informed decision that aligns with your operational goals and enhances overall pressing efficiency.

Future Trends in Isostatic Pressing: Innovations Shaping the Industry

As isostatic pressing continues to evolve, emerging trends are significantly shaping the industry's landscape. The global isostatic pressing market is projected to reach approximately $5 billion by 2027, growing at a CAGR of around 6.5% from 2020. This growth is driven by advancements in technology, such as the integration of Industry 4.0 solutions and automation in manufacturing processes, allowing for enhanced productivity and efficiency.

One of the key innovations in this sector is the development of high-temperature isostatic presses, which enable the production of complex shapes and advanced materials. According to a recent report by The Freedonia Group, the use of advanced ceramics in various applications is on the rise, and this trend is being facilitated by improvements in pressing techniques. Manufacturers are encouraged to invest in these technologies to stay competitive and meet the increasing demand for high-performance materials.

**Tip:** To maximize the efficiency of isostatic pressing, consider investing in predictive maintenance tools. These technologies can identify potential machine failures before they occur, leading to reduced downtime and lower operational costs. Additionally, staying updated with material science advancements can inform better material selection, thereby enhancing the quality of the final product.

Related Posts

-

Resilient Growth of Chinese Manufacturing Amidst US China Tariff Parity for Best Hip Isostatic Pressing

-

2025年热等静压与增材制造的创新之路完整指南

-

Unlocking the Potential of Cladding Hot Isostatic Pressing for Superior Material Performance

-

Exploring Innovative Alternatives in Hip Isostatic Pressing: Trends Shaping 2025 and Beyond

-

Unleashing Efficiency in Manufacturing with Warm Isostatic Press Technology for Global Procurement Leaders

-

Complete Guide to Understanding the Hot Isostatic Pressing Process for Global Manufacturers