What is an Overflow Valve Block and How Does It Work?

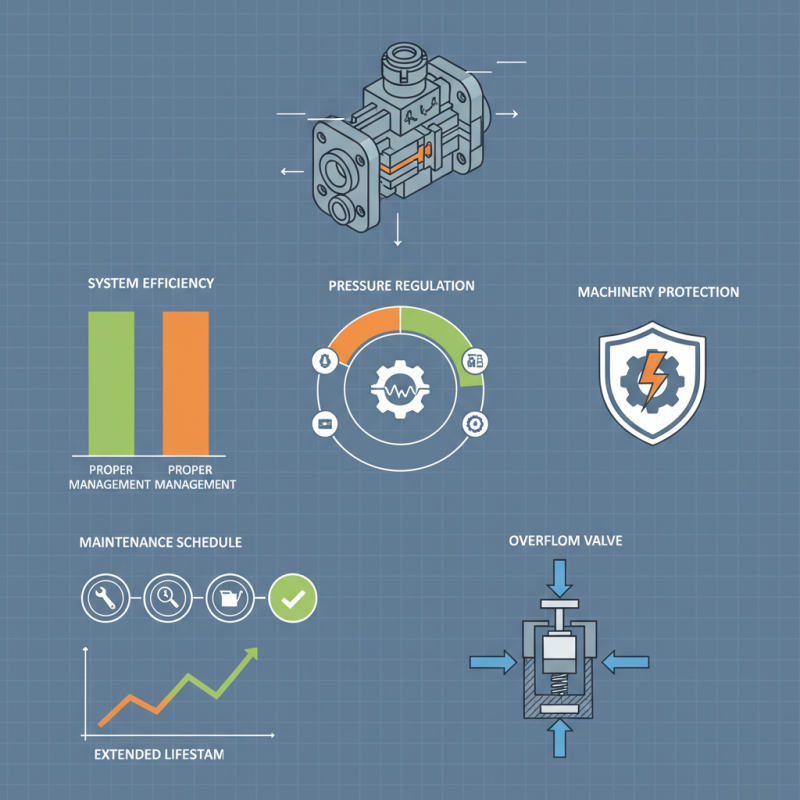

The Overflow Valve Block is crucial in hydraulic systems. It regulates pressure, ensuring safe operation. According to a report by the International Fluid Power Society, improper pressure management can reduce system efficiency by as much as 30%.

Experts emphasize the importance of understanding this component. John Smith, a leading expert in hydraulic technologies, states, "An Overflow Valve Block is vital for protecting machinery from pressure surges." These valves play a critical role in maintaining system stability and reliability.

Many users overlook their maintenance. This can lead to performance issues and costly repairs. Regular inspections are necessary to ensure the Overflow Valve Block functions correctly. Paying attention to this detail can significantly extend the lifespan of hydraulic systems.

Definition and Purpose of an Overflow Valve Block

An overflow valve block is essential in hydraulic systems. It helps maintain pressure and prevents damage. By allowing excess fluid to bypass, it ensures smooth operation. Typically, these blocks are found in various industrial applications.

According to the Hydraulic Components Industry Report 2022, neglecting overflow systems can lead to a 20% reduction in efficiency. This highlights the need for proper implementation and maintenance. A malfunctioning overflow valve can create excess pressure, risking equipment failures.

The design of an overflow valve block may seem simple, yet many overlook its complexity. Accurate calibration is crucial. If set incorrectly, it can lead to leaks or system imbalances. Regular testing and monitoring can prevent costly downtime. A proactive approach is necessary to avoid future issues.

What is an Overflow Valve Block and How Does It Work?

| Feature | Description |

|---|---|

| Definition | An overflow valve block is a hydraulic component designed to control the maximum pressure within a hydraulic system by directing excess flow back to the reservoir. |

| Purpose | To prevent system overpressure, protect components, and ensure safe operation of hydraulic systems. |

| How It Works | When pressure exceeds a preset level, the valve opens to allow excess fluid to flow back, thereby maintaining system pressure within safe limits. |

| Common Applications | Used in various applications including construction machinery, manufacturing equipment, and automotive hydraulic systems. |

| Types | Includes spring-loaded, pilot-operated, and electrically controlled overflow valves. |

| Maintenance Tips | Regularly check for leaks, ensure proper calibration of pressure settings, and replace worn components to maintain efficiency. |

Components of an Overflow Valve Block

An overflow valve block is an essential component in hydraulic systems. It regulates pressure and prevents excess fluid from causing damage. Understanding its components is key to knowing how it operates effectively.

One crucial part of an overflow valve block is the pressure relief valve. This component opens at a predetermined pressure, allowing excess fluid to return to the tank. This prevents system overload. Another important component is the flow control valve. It helps manage the flow rate, ensuring smooth operation. A pressure gauge is also common. It provides real-time monitoring of the system's pressure.

Sometimes, these components malfunction. A stuck pressure relief valve can cause issues. This might lead to excessive pressure or even failure in the system. Regular maintenance can help prevent these problems but often gets overlooked. Don't ignore unusual sounds or fluctuations in pressure, as they can signal impending issues. Evaluating the block and its components regularly is a wise practice.

How an Overflow Valve Block Functions in a System

An overflow valve block plays a crucial role in hydraulic systems. It serves as a control component, ensuring the safe operation of machinery. When pressure exceeds a specific limit, the overflow valve opens to release excess fluid. This prevents potential damage to the system. Imagine a pressurized balloon. If too much air gets inside, it can burst. The overflow valve block works like a safety release for hydraulic systems.

In operation, the overflow valve block connects to the main fluid lines. When the system is functioning normally, fluid flows freely. However, if pressure builds up, the valve activates. It opens and allows fluid to escape into a reservoir. This process is vital for maintaining safe pressure levels. If the valve doesn’t work properly, it can lead to leaks or system failures. There are cases where malfunction occurs, such as sticking valves or incorrect settings.

Operators must regularly inspect overflow valve blocks. Identifying issues early can save time and resources. Observing the flow and pressure can highlight potential problems. It’s essential to reflect on the importance of these components. They might seem simple, but their function is critical. A small oversight can cause significant challenges in hydraulic systems. Understanding how an overflow valve block functions helps in maintaining a well-operating system.

Common Applications of Overflow Valve Blocks

Overflow valve blocks are essential in various industries. They regulate fluid pressure and ensure systems operate safely. Common applications of overflow valve blocks include hydraulic systems, automotive engines, and industrial machinery. In hydraulic systems, they help prevent pressure spikes. This is critical for equipment reliability.

In automotive engines, these valves maintain optimal pressure in fuel and oil systems. A report by the Hydraulic Institute highlights that 45% of hydraulic system failures relate to pressure control issues. This statistic indicates the importance of effective overflow valves in preventing costly breakdowns.

Industrial machinery also relies heavily on overflow valve blocks. They protect equipment from overpressure scenarios. This can reduce downtime and maintenance costs. While these systems are generally reliable, improper installation can lead to failures. Regular monitoring and maintenance are crucial for optimal performance.

Maintenance and Troubleshooting of Overflow Valve Blocks

Maintaining an overflow valve block is crucial for optimal performance. Regular inspections help identify wear and tear. Start by checking the seals. They are often the first parts to degrade. A small crack can lead to significant leaks. These leaks may go unnoticed until it's too late.

Cleaning the valve block is another essential step. Dirt and debris can affect its operation. Use a soft brush and solvent to clean the surface. Make sure to remove any buildup. Consider replacing filters regularly. They can get clogged and cause pressure issues.

Troubleshooting may involve testing the pressure. Use a gauge to see if it's within the recommended range. If it's too high or low, check for blockages. This could be a sign of a failing component. Look for unusual noises during operation. They may indicate internal damage. Reflection on these details can save time and prevent costly repairs.