Ultimate Guide to Optimizing Efficient Hip Manufacturing Processes for Success

In the ever-evolving landscape of modern manufacturing, the efficiency of Hip Manufacturing processes plays a critical role in determining the success and competitiveness of businesses. As companies strive to streamline operations, reduce costs, and enhance product quality, understanding the benefits of optimized manufacturing techniques becomes paramount. This ultimate guide delves into various strategies for improving Hip Manufacturing, highlighting how effective process optimization can lead to increased productivity, minimized waste, and faster time-to-market.

By exploring best practices, advanced technologies, and innovative solutions, we aim to equip manufacturers with the knowledge and tools necessary to thrive in a highly competitive marketplace. Whether you are a seasoned professional or a newcomer to the industry, this blog will provide valuable insights into the transformative benefits of refining Hip Manufacturing processes for sustained success.

Understanding the Core Principles of Hip Manufacturing Efficiency

Understanding the core principles of hip manufacturing efficiency is crucial for optimizing production processes and driving success in this competitive industry. Lean production, a management philosophy that prioritizes value creation while significantly reducing waste, serves as a foundational approach. In a well-implemented lean environment, manufacturers can achieve improvements that lead to increased productivity and reduced operational costs. A report by the Lean Enterprise Institute indicates that companies applying lean techniques can enhance their efficiency by up to 30%, showcasing the profound impact of this philosophy on manufacturing outcomes.

One of the pivotal concepts in optimizing hip manufacturing processes is the 80-20 Rule, or Pareto Principle. This principle highlights that often, 80% of the results come from just 20% of the efforts. In the context of hip manufacturing, it's essential to identify and focus on the key processes and resources that drive the majority of production efficiency. According to industry research, identifying these critical inputs can not only streamline operations but also facilitate significant cost savings—reportedly up to 25% in some cases—by eliminating inefficiencies. By concentrating on the elements that yield the highest returns, manufacturers can create a more productive and responsive operational framework.

Leveraging Digital Technologies for Enhanced Production Processes

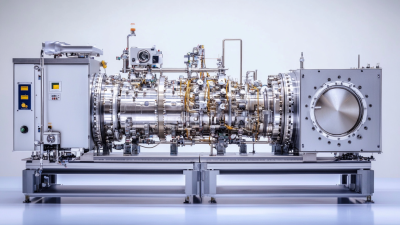

In the fast-paced world of hip manufacturing, leveraging digital technologies is crucial for enhancing production processes. Advanced technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and machine learning provide manufacturers with the tools needed to optimize operations, reduce waste, and improve overall efficiency. By implementing IoT devices, manufacturers can collect real-time data on machine performance and production output, allowing for informed decision-making and timely maintenance. This not only minimizes downtime but also enhances productivity by ensuring that resources are used efficiently.

Furthermore, AI-driven analytics can identify patterns and trends within the manufacturing process, enabling companies to predict potential bottlenecks and streamline workflows. By analyzing historical data, manufacturers can optimize scheduling and resource allocation, ensuring that production lines run smoothly. Additionally, digital twin technology allows for simulation of manufacturing processes in a virtual environment, helping businesses explore various scenarios and identify the best strategies for implementation. The integration of these digital solutions fundamentally transforms hip manufacturing, setting a new standard for operational excellence and economic success.

Key Metrics for Measuring Efficiency in Hip Manufacturing

When optimizing hip manufacturing processes, measuring efficiency is paramount. Key metrics play a crucial role in identifying areas for improvement and ensuring that production meets high standards. One essential metric is the Overall Equipment Effectiveness (OEE), which combines availability, performance, and quality to provide a comprehensive view of production efficiency. By focusing on OEE, manufacturers can pinpoint bottlenecks, reduce downtime, and enhance overall productivity.

Another critical metric is the First Pass Yield (FPY), which indicates the percentage of products manufactured correctly without rework. High FPY not only reduces costs associated with material and labor but also reflects the effectiveness of the manufacturing process. Tracking FPY allows manufacturers to assess the quality of their processes and implement corrective actions swiftly. Furthermore, cycle time measurement is essential for understanding the time taken to complete each production cycle. By analyzing cycle times, manufacturers can streamline operations, reduce waste, and ultimately achieve greater efficiency in hip production.

Ultimate Guide to Optimizing Efficient Hip Manufacturing Processes for Success - Key Metrics for Measuring Efficiency in Hip Manufacturing

| Metric | Description | Current Value | Target Value | Improvement Needed (%) |

|---|---|---|---|---|

| Cycle Time | Time taken to complete one manufacturing cycle | 45 mins | 30 mins | 33.33% |

| First Pass Yield | Percentage of products manufactured correctly without rework | 85% | 95% | 11.76% |

| Overall Equipment Effectiveness (OEE) | Measure of operational efficiency | 75% | 90% | 20% |

| Downtime | Total time machinery is not operational | 10 hours/week | 3 hours/week | 70% |

| Material Waste | Percentage of materials wasted during production | 5% | 2% | 60% |

Streamlining Supply Chain Management for Optimal Hip Production

In the contemporary landscape of hip manufacturing, effective supply chain management is vital for ensuring optimal production processes. By streamlining various supply chain components, manufacturers can significantly reduce lead times and enhance productivity. This begins with fostering robust relationships with suppliers, ensuring that high-quality materials are consistently available. Implementing just-in-time inventory management can also minimize excess stock costs and improve responsiveness to market demands, allowing manufacturers to pivot quickly as needed.

Moreover, leveraging technology in supply chain operations can further enhance efficiency. Utilizing advanced data analytics and automation tools allows manufacturers to predict trends, manage inventory more effectively, and streamline logistics. Real-time tracking and monitoring systems can provide insights into every stage of the production journey, helping to identify bottlenecks and optimize workflows. By embracing these strategies, hip manufacturers not only improve their operational efficiency but also position themselves to meet customer demands with greater agility, ultimately contributing to their overall success in the market.

Best Practices for Continuous Improvement in Hip Manufacturing Processes

In the competitive landscape of hip manufacturing, continuous improvement is crucial for enhancing efficiency and ensuring product quality. Implementing best practices can significantly streamline processes and reduce waste. One effective strategy is to adopt lean manufacturing principles, which focus on minimizing non-value-added activities. By analyzing workflows and identifying bottlenecks, manufacturers can create more efficient processes that promote speed and responsiveness.

Tips for continuous improvement include regular training sessions for staff to ensure they are up to date with the latest manufacturing techniques and technologies. Encouraging feedback from employees on the production floor often leads to innovative solutions that enhance performance. Another key practice is the use of data analytics to monitor production metrics; this enables manufacturers to make informed decisions based on real-time insights, driving sustained improvement.

Lastly, fostering a culture of collaboration and open communication can lead to significant enhancements in hip manufacturing processes. Engaging teams in problem-solving initiatives not only builds morale but also uncovers valuable insights that contribute to refinement and efficiency. By cultivating an environment where continuous improvement is a shared goal, manufacturers can position themselves for success in the ever-evolving industry.

Related Posts

-

Innovative Solutions for High Quality Isostatic Pressing Services

-

5 Reasons Why Best Cold Isostatic Compaction is Key to Achieving 90 Percent Material Efficiency

-

2025年热等静压与增材制造的创新之路完整指南

-

Understanding the Advantages of Hot Isostatic Pressing Technology for Global Suppliers

-

Challenges Faced in Vacuum Sintering Furnace Operations Impacting Productivity

-

Comprehensive Insights into Hot Isostatic Pressing Additive Manufacturing for Global Buyers