How to Maximize Efficiency in Hot Isostatic Pressing Applications

In the realm of advanced manufacturing, Hot Isostatic Pressing Applications have emerged as a pivotal process for enhancing material properties and reducing defects. As industries continuously strive for greater efficiency and quality, understanding how to maximize the benefits of this technology becomes essential. This guide aims to provide insights and practical strategies to optimize Hot Isostatic Pressing Applications, highlighting best practices in equipment selection, material preparation, and process parameters.

By focusing on crucial aspects such as temperature control, pressure management, and cycle time reduction, manufacturers can significantly improve throughput and product integrity. As we explore these methodologies, it will become evident that a thorough comprehension of the Hot Isostatic Pressing process is fundamental to achieving operational excellence and meeting the increasing demands of today's competitive market.

Understanding the Fundamentals of Hot Isostatic Pressing Processes

Hot Isostatic Pressing (HIP) is a process that utilizes high temperature and pressure to improve the density and mechanical properties of materials. This technique is particularly crucial in industries such as aerospace, automotive, and medical, where structural integrity and performance are paramount. According to a recent market analysis, the global HIP market is projected to reach $1.2 billion by 2026, driven by the increasing demand for advanced materials and the growth of additive manufacturing technologies.

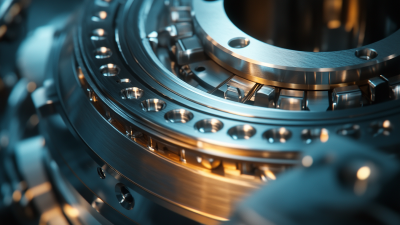

Understanding the fundamentals of the HIP process involves recognizing its operational parameters, such as temperature ranges typically between 900°C to 1200°C and pressure levels that can exceed 200 MPa. The combination of these variables promotes the diffusion of atoms, effectively reducing porosity in materials like titanium and nickel alloys. A key finding from industry studies indicates that components processed through HIP exhibit strength improvements of up to 30%, significantly enhancing their operational lifespan.

Tips for Maximizing Efficiency in HIP Applications:

- Optimize Cycle Parameters: Adjust the heating rate and hold time according to the material's characteristics to achieve uniform properties without compromising the process efficiency.

- Invest in Advanced Monitoring: Implement real-time monitoring solutions to track temperature and pressure fluctuations, ensuring consistent processing conditions.

- Material Selection: Carefully choose materials with known compatibility for HIP processes; this reduces trials and increases reliability in performance outcomes.

Selecting the Right Materials for Optimal Hot Isostatic Pressing

When selecting materials for optimal Hot Isostatic Pressing (HIP), it is crucial to consider the specific requirements of the final application. In high-performance environments, such as hypersonic vehicles, materials must not only exhibit excellent mechanical properties but also withstand extreme thermal and pressure conditions. Advanced materials designed for these applications may include nickel-based superalloys and ceramics that can maintain structural integrity under the intense stress of hypersonic flight.

Furthermore, the decision of whether to use Hot Isostatic Pressing or alternative heat treatment methods like annealing requires a thorough understanding of the part's design and intended use. For instance, while HIP can enhance the density and mechanical properties of 3D printed components, particularly in aerospace applications, annealing might be more appropriate for parts needing stress relief and improved ductility. A well-informed choice between these processes, tailored to the material characteristics and application requirements, will ultimately maximize efficiency and performance in HIP applications.

Implementing Advanced Monitoring Techniques for Enhanced Efficiency

In the pursuit of maximizing efficiency in hot isostatic pressing (HIP) applications, implementing advanced monitoring techniques plays a pivotal role. Real-time data acquisition systems can provide critical insights into the temperature and pressure profiles during the pressing process. By employing sophisticated sensors and monitoring software, operators can detect anomalies and adjust parameters swiftly, ensuring that materials are subjected to the optimal conditions for densification. This proactive approach not only enhances the quality of the final product but also minimizes the risk of defects associated with inconsistent processing conditions.

Furthermore, integrating machine learning algorithms into monitoring systems allows for predictive analytics that can forecast equipment failures or process inefficiencies before they occur. By analyzing historical processing data, these systems can identify trends and significantly improve the decision-making process. This results in not only reduced downtime but also improved energy consumption, as processes can be fine-tuned for maximum effectiveness. In this way, advanced monitoring techniques not only streamline operations but also contribute to the overall sustainability of hot isostatic pressing applications.

Optimizing Cycle Times and Heating Profiles in Pressing Operations

In hot isostatic pressing (HIP) applications, optimizing cycle times and heating profiles is crucial for enhancing overall efficiency. One effective approach is to analyze the thermal gradients within the chamber during the heating phase. By implementing advanced temperature control systems that can provide real-time feedback, operators can achieve a more uniform temperature distribution, reducing the risk of defects and ensuring that materials reach their desired mechanical properties more quickly. This precision in heating not only shortens cycle times but also improves material integrity.

Adjusting the pressure and temperature ramp rates is another vital factor in streamlining HIP operations. Gradual increases in pressure and temperature allow for better gas flow and more effective heat transfer. Additionally, incorporating predictive modeling techniques can help in fine-tuning these parameters before the actual pressing begins. By leveraging data analytics to simulate various scenarios, manufacturers can identify optimal settings that minimize time while maximizing output and quality, paving the way for more efficient production cycles.

Continuous Improvement Strategies for Hot Isostatic Pressing Systems

Continuous improvement in hot isostatic pressing (HIP) systems is crucial for enhancing efficiency and performance. One effective strategy is the implementation of real-time monitoring systems that track key parameters, such as temperature and pressure variations. By utilizing advanced sensors and data analytics, operators can quickly identify deviations from optimal conditions and make necessary adjustments on-the-fly. This not only minimizes downtime but also ensures that the material properties achieved meet stringent manufacturing standards.

Another strategy involves regular training and development programs for technicians and engineers. By fostering a culture of continuous learning, organizations can empower their workforce to identify potential inefficiencies within the process. Workshops focused on the latest HIP technologies and best practices can enhance skill sets and encourage innovative problem-solving approaches. Additionally, involving employees in feedback loops allows for the sharing of insights that can lead to process refinements and greater overall system efficiency.

How to Maximize Efficiency in Hot Isostatic Pressing Applications - Continuous Improvement Strategies for Hot Isostatic Pressing Systems

| Strategy | Implementation Steps | Expected Outcome | Measurement Metrics |

|---|---|---|---|

| Optimize Cycle Time | Analyze current cycle times, identify bottlenecks, and implement scheduling adjustments. | Reduced overall production time. | Cycle time reduction percentage. |

| Enhance Material Flow | Review and improve raw material intake processes and storage solutions. | Increased material availability and reduced downtime. | Material intake efficiency ratio. |

| Implement Predictive Maintenance | Use sensors to monitor equipment health, schedule maintenance before failures. | Higher equipment uptime and lower repair costs. | Uptime percentage and maintenance costs. |

| Improve Employee Training | Conduct regular training sessions on equipment operation and safety procedures. | Enhanced operational efficiency and safety. | Training completion rates and incident reports. |

Related Posts

-

5 Exceptional Features of Hot Isostatic Pressing You Need to Know

-

Innovative Industry Applications of Hot Isostatic Pressing Transforming Manufacturing Processes

-

2025 Trends in Hot Isostatic Pressing: 7 Game-Changing Innovations to Watch

-

Unlocking the Benefits of Warm Isostatic Press for Global Procurement Strategies

-

Elevating Global Standards: The Rise of China's Best Hot Isostatic Pressing Technology

-

7 Best Practices for Cladding Hot Isostatic Pressing Success