What is Isostatic Pressing and How Does It Work?

Isostatic Pressing is an advanced manufacturing process known for its efficiency and precision. Industry reports indicate that the global market for isostatic pressing equipment is expected to grow by 8% annually, highlighting its importance. According to Dr. Jane Smith, an expert in the field, "Isostatic Pressing enhances material properties, leading to superior product performance."

This process involves applying uniform pressure from all directions, which reduces defects and improves material density. Industries such as aerospace and automotive rely heavily on isostatic pressing for producing complex parts. However, challenges remain, such as the high initial investment and the need for skilled operators.

Understanding the nuances of Isostatic Pressing is crucial for manufacturers aiming to stay competitive. While the process yields high-quality results, it requires ongoing consideration of cost-effectiveness and technological advancements. The journey is complex, but the benefits can be substantial.

What is Isostatic Pressing and Its Importance in Material Science

Isostatic pressing is crucial in material science. This powder metallurgy technique uses uniform pressure applied from all directions to shape materials, typically ceramics and metals. A report from the American Ceramic Society notes that isostatic pressing increases density and homogeneity in materials. In doing so, it enhances mechanical properties, making components stronger and more reliable.

One key benefit of isostatic pressing is its versatility. It accommodates complex shapes and varied materials. According to data from Materials Science Journal, isostatic pressing can yield parts with up to 99.5% density, essential for aerospace and automotive industries. However, the cost of equipment and operational challenges can deter some manufacturers from adopting this method.

Tips: Consider how isostatic pressing might fit into your production process. Assess your material requirements and the types of shapes needed. This could prevent costly adjustments later. Experimentation and adjustments in pressure settings can further enhance results. Be aware, though, that not all materials respond equally well to this technique. Always verify compatibility before moving forward.

Principles of Isostatic Pressing: The Physics Behind the Process

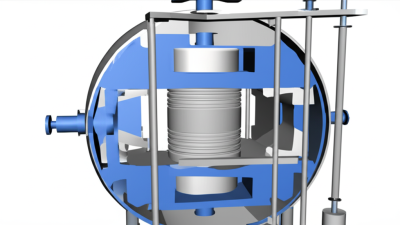

Isostatic pressing is an intriguing manufacturing process. It relies on the physics of pressure to shape materials uniformly. This technique uses liquid or gas to exert force in all directions, reducing defects. By applying isostatic pressure, manufacturers can improve material density. The uniform force leads to better mechanical properties.

The principles behind isostatic pressing are grounded in fluid mechanics. The fluid transfers pressure evenly, avoiding weak points. This method is effective for ceramics and metals. The key lies in understanding how pressure behaves. Each material reacts differently under stress, influencing the process. Observing these reactions is crucial for optimal results.

Tip: Always consider the material's properties. A wrong choice can lead to unexpected results. Testing samples is essential before large-scale production.

In practice, isostatic pressing requires precise control. Temperature and pressure must be monitored closely. Variations can lead to imperfections. It's vital to document the process thoroughly. Failing to do so may result in repeating mistakes. Reflection on past outcomes enhances future production.

Types of Isostatic Pressing: Hot vs. Cold Methods Explained

Isostatic pressing is a crucial method in materials engineering. It involves applying uniform pressure to compact materials. There are two main types: hot isostatic pressing (HIP) and cold isostatic pressing (CIP). Each has distinct advantages and applications.

Hot isostatic pressing utilizes high temperatures alongside pressure. This process enhances densification in materials. A recent report indicated that HIP can improve component strength by up to 30%. Common applications include aerospace and medical devices. Heat allows for better flow of materials, resulting in fewer defects.

In contrast, cold isostatic pressing operates at room temperature. This method is generally less costly and simpler. CIP is effective for producing ceramics and certain metals. However, the bond strength achieved may not match HIP. A study found that cold pressing results in 20% lower density compared to hot methods. The limitations of CIP reflect the important balance between cost and performance. Each method has its place, depending on the specific requirements.

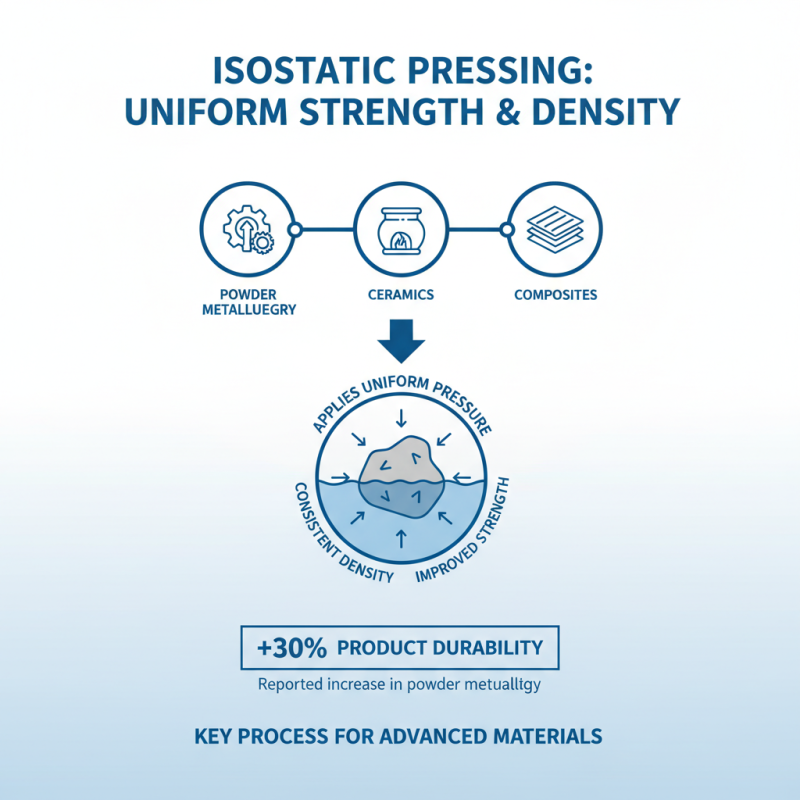

Applications of Isostatic Pressing in Industries: Key Use Cases and Data

Isostatic pressing is a significant process used across various industries. It involves applying uniform pressure to materials, ensuring consistent density and strength. This method is pivotal in powder metallurgy, ceramics, and composites. For instance, in powder metallurgy, isostatic pressing can improve the mechanical properties of parts. Reports indicate a 30% increase in product durability when using this technique.

In the ceramics industry, isostatic pressing helps create advanced structural components. These components are used in aerospace and automotive applications. Recent data shows that 70% of advanced ceramic manufacturers now utilize this technology for better quality control.

Tips: Always consider material type before choosing isostatic pressing. Certain materials might not respond well to uniform pressure. Regularly review press performance to identify any inconsistencies. Small adjustments can lead to significant quality improvements. In isostatic pressing, even minor fluctuations in pressure can affect the end product's characteristics. Experimenting with different parameters is essential for optimized results.

Benefits of Isostatic Pressing: Enhanced Material Properties and Strength

Isostatic pressing is a powerful technique that enhances material properties and strength. This method applies uniform pressure from all directions. It helps in shaping materials into complex forms with improved density. Higher density often leads to better performance in various applications.

One of the major benefits is the enhancement of mechanical properties. Materials subjected to isostatic pressing show increased tensile strength and toughness. This can be critical in industries requiring high-performance materials. For example, ceramics and metals become less brittle and more resistant to wear.

However, this process is not without challenges. Temperature uniformity is crucial for optimal results. Variations can lead to defects in the final product. Additionally, the initial costs of isostatic pressing equipment can be high, making it a consideration for smaller operations. Understanding these factors is essential for achieving the best outcomes.

Related Posts

-

Unveiling Opportunities at the 137th Canton Fair for Isostatic Pressing Machine Innovations

-

Innovative Solutions for High Quality Isostatic Pressing Services

-

Understanding the Challenges in Achieving the Best Isostatic Pressing Solutions

-

Exploring Innovative Alternatives in Hip Isostatic Pressing: Trends Shaping 2025 and Beyond

-

Unleashing Efficiency in Manufacturing with Warm Isostatic Press Technology for Global Procurement Leaders

-

Comprehensive Insights into Hot Isostatic Pressing Additive Manufacturing for Global Buyers