Ultimate Guide to Understanding Hot Isostatic Pressing Machine Applications and Benefits

In the rapidly evolving world of manufacturing, the Hot Isostatic Pressing Machine (HIP) has emerged as a pivotal technology, offering unparalleled advantages in enhancing the mechanical properties of materials. According to a report by MarketsandMarkets, the global HIP market is projected to reach USD 2.4 billion by 2025, driven by the increasing demand for advanced materials in aerospace, automotive, and medical industries. This method not only improves the density and strength of components but also eliminates defects, making it an ideal solution for producing high-performance parts.

As industries continue to strive for efficiency and innovation, understanding the applications and benefits of Hot Isostatic Pressing will be crucial for businesses looking to leverage this technology effectively. This ultimate guide will delve into the key reasons why the HIP process is revolutionizing modern manufacturing and where its applications are making the most significant impact.

As industries continue to strive for efficiency and innovation, understanding the applications and benefits of Hot Isostatic Pressing will be crucial for businesses looking to leverage this technology effectively. This ultimate guide will delve into the key reasons why the HIP process is revolutionizing modern manufacturing and where its applications are making the most significant impact.

Key Applications of Hot Isostatic Pressing Machines in Various Industries

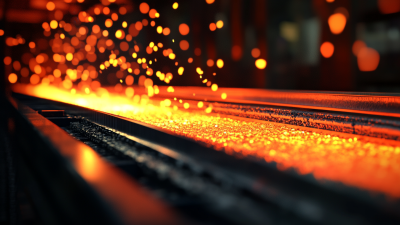

Hot Isostatic Pressing (HIP) is a crucial process that significantly enhances material properties across various industries. This innovative technique is widely adopted in aerospace, automotive, and medical sectors, where the integrity and performance of components are paramount. By applying high temperatures and uniform pressure, HIP effectively reduces porosity and improves the mechanical strength of metals and ceramics, making them more durable and reliable for demanding applications.

In aerospace, HIP is particularly beneficial for manufacturing engine components and structural parts. The process allows for the creation of lightweight yet strong materials that can withstand extreme conditions. Similarly, the automotive industry relies on HIP for producing high-performance parts, such as pistons and gearboxes, ensuring they meet rigorous safety and efficiency standards. In the medical field, HIP is essential for fabricating intricate implants that require optimal biocompatibility and mechanical properties.

**Tips:** When considering HIP for your manufacturing processes, it's essential to collaborate with experienced professionals who understand material behaviors under pressure. Additionally, conducting thorough testing after HIP treatment can ensure that your components perform as expected in real-world applications. Finally, always stay updated on advancements in HIP technology, as new methods and materials can further enhance your production efficiency and product quality.

Understanding the Benefits of Hot Isostatic Pressing for Material Strengthening

Hot Isostatic Pressing (HIP) is a crucial process in material science that significantly enhances the mechanical properties of metals and ceramics. This method involves applying high temperature and pressure uniformly in all directions, which effectively eliminates internal voids and imperfections within materials. As a result, the microstructure of the treated materials becomes more refined, leading to improved density and strength. Industries such as aerospace, automotive, and medical are increasingly utilizing HIP to produce components that must endure high stress and extreme conditions.

One of the key benefits of Hot Isostatic Pressing is its ability to enhance the fatigue resistance and overall durability of materials. By densifying the structure, HIP treatment reduces the likelihood of crack propagation, which is especially important in applications where reliability is paramount. Additionally, the process can enable the use of advanced materials that may be challenging to work with otherwise, allowing for innovative designs and improved performance in end products. This makes HIP not just a fabrication technique, but a vital solution for engineering challenges across various sectors.

Checklist: Essential Factors to Consider When Choosing a Hot Isostatic Pressing Machine

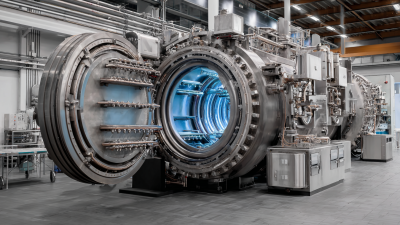

When selecting a hot isostatic pressing (HIP) machine, several essential factors must be considered to ensure optimal performance and suitability for your specific applications. First and foremost, the size and capacity of the machine are critical. This includes assessing the maximum part dimensions and the volume of materials you plan to process. A machine that meets your production requirements can significantly enhance efficiency and reduce cycle times.

Another key factor is the operating pressure and temperature range of the HIP machine. Different materials, such as ceramics, metals, and composites, require varying conditions for effective processing. Understanding the specific needs of your materials will guide you in choosing a machine that can achieve the desired densification and mechanical properties. Additionally, it is vital to evaluate the machine's control systems and automation features, as these can greatly impact precision and repeatability in production processes. Investing in a sophisticated control system can also facilitate easier monitoring and data collection, leading to improved operational insights.

Common Mistakes to Avoid When Implementing Hot Isostatic Pressing Techniques

When implementing hot isostatic pressing (HIP) techniques, manufacturers must be vigilant in avoiding common pitfalls that can compromise the efficacy of the process. One major mistake is inadequate preparation of the materials. Materials must be meticulously cleaned and characterized to ensure optimal performance during HIP. Failure to do so can lead to defects, such as incomplete densification or the presence of impurities that may affect the final product quality.

Another frequent error is neglecting to understand the specific requirements of the materials being pressed. Different materials, including metals, ceramics, and composites, have distinct thermal and mechanical properties that influence their behavior under high pressure and temperature. Without a tailored approach, operators risk suboptimal processing conditions, which can further lead to product inconsistencies or even failure.

Lastly, overlooking the importance of process monitoring and control can undermine the benefits of HIP. Establishing a comprehensive monitoring system helps to track key parameters throughout the pressing cycle, ensuring consistency and quality in the final components. By avoiding these mistakes, companies can fully leverage the advantages of hot isostatic pressing, ultimately enhancing product performance and extending their market competitiveness.

Applications and Benefits of Hot Isostatic Pressing

Future Trends in Hot Isostatic Pressing Technology and Applications

The landscape of Hot Isostatic Pressing (HIP) technology is evolving rapidly, with exciting innovations that promise to reshape its applications across various industries. The introduction of a new HIP system, exemplified by a recent launch, highlights the ongoing advancements in high-pressure technology, signaling a future where efficiency and precision are paramount. As industries such as aerospace, medical, and energy embrace more sophisticated materials and manufacturing techniques, HIP machines are becoming vital in producing components with enhanced mechanical properties and finer microstructures.

In particular, the integration of additive manufacturing (AM) techniques is unlocking new potentials for HIP applications. Recent breakthroughs in designing orthopedic implants using topology optimization are revolutionizing bone repair surgeries, demonstrating how combining AM with HIP can yield superior material properties tailored for specific medical needs. Furthermore, the growing interest in high-entropy alloys and thermoelectric materials reflects a shift toward innovative applications, with HIP technology playing a crucial role in enhancing the performance and reliability of these advanced materials. As these trends continue to develop, the future of HIP technology promises to bring forth more efficient, durable, and application-specific solutions that cater to the demands of modern engineering challenges.

Ultimate Guide to Understanding Hot Isostatic Pressing Machine Applications and Benefits - Future Trends in Hot Isostatic Pressing Technology and Applications

| Application Area | Benefits | Future Trends |

|---|---|---|

| Aerospace | Improved material strength and reduced weight. | Adoption of advanced ceramic materials. |

| Medical Devices | Enhanced biocompatibility and mechanical properties. | Integration with additive manufacturing techniques. |

| Automotive | Increased durability and performance of parts. | Focus on lightweighting and efficiency improvements. |

| Energy Sector | Enhanced performance of turbine components. | Use of HIPP for renewable energy applications. |

| Tooling and Dies | Increased lifespan and performance of tooling. | Smart manufacturing integration for real-time monitoring. |

Related Posts

-

Exploring Innovative Alternatives in Hip Isostatic Pressing: Trends Shaping 2025 and Beyond

-

Unleashing Efficiency in Manufacturing with Warm Isostatic Press Technology for Global Procurement Leaders

-

2025 Trends in Hot Isostatic Pressing: 7 Game-Changing Innovations to Watch

-

Resilient Growth of Chinese Manufacturing Amidst US China Tariff Parity for Best Hip Isostatic Pressing

-

Market Trends and Predictions for the Best Cold Isostatic Pressing Machines by 2025

-

Mastering Isostatic Pressing: A Comprehensive Guide to the Best Ceramic Solutions