Ultimate Guide to Selecting the Right Hot Isostatic Pressing Equipment for Your Manufacturing Needs

In the ever-evolving landscape of manufacturing, the selection of the right Hot Isostatic Pressing Equipment has emerged as a critical factor for companies aiming to enhance product quality and operational efficiency. According to a recent market analysis by Smithers, the global hot isostatic pressing market is projected to reach $1.5 billion by 2025, driven by increasing demand for high-performance materials in aerospace, automotive, and medical sectors. This growth underscores the importance of investing in advanced equipment that can deliver uniform densification and improved mechanical properties. As manufacturers navigate this complex decision-making process, understanding the key features and specifications of hot isostatic pressing systems becomes paramount not only for optimizing production but also for staying competitive in a market that increasingly prioritizes precision and innovation.

Understanding Hot Isostatic Pressing: Key Concepts and Benefits

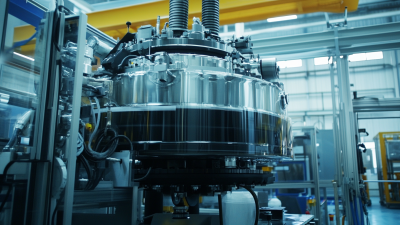

Hot Isostatic Pressing (HIP) is a sophisticated manufacturing process that enhances the density and mechanical properties of materials, making it a preferred choice in various industries, including aerospace, automotive, and medical devices. The technique involves subjecting materials to high temperature and pressure simultaneously, allowing for uniform heat distribution and pressure application. This unique combination aids in eliminating porosity and improving the overall structural integrity of components, leading to enhanced performance and longevity.

One of the key benefits of HIP is its ability to process complex geometries that would be challenging or impossible to achieve through traditional manufacturing methods. This capability not only increases design flexibility but also minimizes material waste, which is crucial in today's sustainability-focused manufacturing landscape. Moreover, HIP can significantly reduce secondary processing requirements, streamlining production timelines and reducing costs. Understanding these concepts is essential for manufacturers looking to optimize their processes and achieve superior product quality.

Factors to Consider When Choosing Hot Isostatic Pressing Equipment

When selecting hot isostatic pressing (HIP) equipment for your manufacturing needs, several factors warrant careful consideration. One of the most critical aspects is the type of materials you plan to process. Different materials respond uniquely to HIP treatments, and understanding how the process can enhance properties like density and mechanical strength is essential. Manufacturers should assess the specific requirements of their materials—whether it be metal powders or composites—to ensure the selected equipment optimally facilitates desired outcomes.

Operational capacity is another vital factor. As the demand for advanced manufacturing techniques increases, the ability of your HIP equipment to handle larger batches or more complex geometries becomes crucial. Additionally, energy efficiency and cycle times play significant roles in overall productivity. By investigating the latest advancements in HIP technologies, such as those that improve quality and performance of additive manufacturing parts, you can make informed decisions that align with your operational goals while ensuring competitiveness in the market. Other considerations include ease of integration with existing processes, maintenance requirements, and the availability of technical support.

Ultimate Guide to Selecting the Right Hot Isostatic Pressing Equipment for Your Manufacturing Needs

| Factor | Description | Importance Level | Recommended Range |

|---|---|---|---|

| Pressure Capability | The maximum pressure the equipment can achieve, measured in psi or MPa. | High | Up to 30,000 psi |

| Temperature Range | The range of temperatures the press can operate at, essential for different materials. | High | Up to 2000 °F |

| Hold Time | Duration for which the pressure and temperature are maintained during the process. | Medium | From 1 hour to 10 hours |

| Cooling Rate | The speed at which the equipment can cool down after processing. | Medium | Varies by design, typically < 2 °F/min |

| Footprint | The space required for the equipment, which can impact facility layout. | Low | Typically ranges from 10 to 50 square feet |

| User Interface | Ease of use and accessibility of controls for operators. | Medium | Intuitive and simplified interface recommended |

Comparing Different Types of Hot Isostatic Pressing Systems

Hot Isostatic Pressing (HIP) has emerged as a pivotal technique in manufacturing, particularly when evaluating its effectiveness compared to other heat treatment processes such as annealing. A recent study revealed that HIP significantly enhances the mechanical properties of materials such as Hastelloy X produced through electron beam powder bed fusion. The experiments indicated that applying solution heat treatment (SHT) followed by HIP reduced porosity and refined the microstructure, leading to superior mechanical performance in comparison to as-built specifications.

Moreover, advancements in HIP methodologies, such as the innovative two-step densification process, have demonstrated remarkable results in achieving fully-densified structures, especially in wooden materials. This method not only enhances physical properties but also improves mechanical strength significantly, suggesting its potential application in various industries. Research highlights that this approach can yield material performance improvements by up to 30% in specific contexts, making it an attractive option for manufacturers looking for effective processing techniques. The choice between hot isostatic pressing and traditional annealing should consider not only the desired material properties but also efficiency and the specific manufacturing environment, as each treatment has its unique advantages.

Maintenance and Safety Considerations for Pressing Equipment

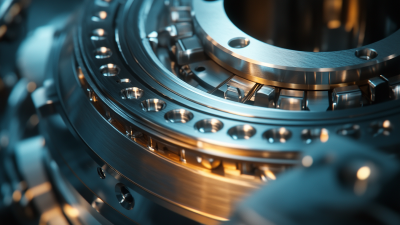

When utilizing hot isostatic pressing (HIP) equipment, prioritizing maintenance and safety is crucial to ensure optimal performance and longevity. Regular maintenance not only minimizes potential downtimes but also enhances safety protocols. According to a report from the International Journal of Machine Tools and Manufacture, equipment failures in HIP can lead to production losses averaging 16% in high-demand sectors. Implementing a structured maintenance schedule can reduce these failures significantly.

**Tips:** Always conduct routine inspections to assess wear and tear on critical components, such as pressure vessels and seals. Additionally, ensuring that safety interlocks and alarms are functioning properly can prevent hazardous incidents, as noted by the Occupational Safety and Health Administration (OSHA), which emphasizes the importance of adhering to safety standards to prevent workplace accidents.

Moreover, operators should be trained in emergency response procedures. Engaging in regular safety drills not only prepares staff for potential hazards but also reinforces a culture of safety within the workplace. A recent study revealed that companies with robust safety training programs reported 30% fewer incidents related to equipment misuse. Providing continuous education on the safe handling and operational procedures of HIP equipment significantly contributes to a safe manufacturing environment.

Cost Analysis: Budgeting for Hot Isostatic Pressing Solutions

When budgeting for hot isostatic pressing (HIP) solutions, one must consider various factors that significantly impact the overall cost. First and foremost, the initial investment in HIP equipment can vary widely based on the features, manufacturing capabilities, and the specific technology used. Advanced systems often come with higher price tags but offer enhanced performance and efficiency, potentially leading to cost savings in the long run. Additionally, it’s crucial to account for installation costs, which can include site preparation and specialized utilities required for operation.

Beyond the initial purchase, operational costs must also be evaluated. This includes maintenance, energy consumption, and the cost of consumables that keep the equipment running smoothly. Moreover, training personnel to operate the HIP equipment safely and effectively adds to the financial consideration. Organizations should also analyze the material costs associated with the specific applications they plan to undertake, as this can influence the choice of equipment. A thorough cost analysis will ensure businesses not only select the appropriate HIP equipment but also align it with their budgetary constraints and operational needs.

Related Posts

-

Discovering Top Quality Suppliers for Hot Isostatic Pressing Equipment with Essential Evaluation Steps

-

Challenges Facing Global Buyers of Hot Isostatic Pressing Equipment

-

2025 Trends in Hot Isostatic Pressing: 7 Game-Changing Innovations to Watch

-

Innovative Industry Applications of Hot Isostatic Pressing Transforming Manufacturing Processes

-

5 Exceptional Features of Hot Isostatic Pressing You Need to Know

-

Understanding the Advantages of Hot Isostatic Pressing Technology for Global Suppliers