How to Choose the Right Saw Swing for Your Projects?

Choosing the right saw-swing for your projects is crucial for achieving precision and efficiency. Expert Mark Thompson emphasizes, “A well-chosen saw-swing can transform your woodworking experience.” Selecting the appropriate swing involves understanding your specific needs and the materials you're working with.

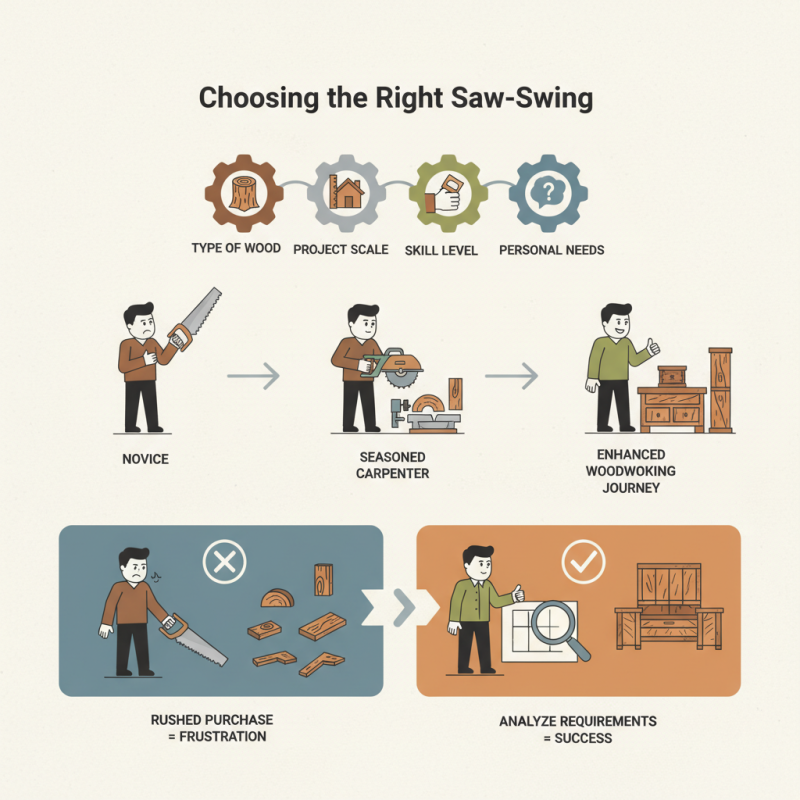

Many factors influence the choice of saw-swing. These include the type of wood, the project's scale, and your personal skill level. A novice might opt for a simpler, more forgiving saw-swing. In contrast, a seasoned carpenter may prefer advanced options for intricate designs. It's vital to reflect on your experiences and whether your current tools serve you effectively.

Mistakes do happen, and the decision can lead to frustration. Some users might rush into a purchase, only to realize later it doesn’t suit their work style. Taking the time to analyze your requirements can prevent this pitfall. You may find that a different saw-swing offers better results for your specific projects. Balancing your ambitions with the right tool choices can ultimately enhance your woodworking journey.

Understanding Different Types of Saw Swings for Various Projects

Choosing the right saw swing is crucial for your woodworking projects. Each type of saw swing has its specific advantages and disadvantages. Understanding these characteristics can lead to better results. Different styles accommodate various materials and cuts. Some saws are designed for detailed work, while others excel at rough cuts.

When selecting a saw swing, consider the project type. For intricate designs, a scroll saw might be ideal. It allows for delicate curves and patterns. On the other hand, a table saw is perfect for straight cuts on larger pieces. But do not overlook the miter saw. It’s great for angled cuts and precise crosscuts.

Tips: Always check the blade type. A fine-toothed blade works better for hardwood. But a coarse blade is useful for softwood. Don’t forget to evaluate safety features. Equipment should have guards and brakes to prevent accidents. Reflect on your skill level too. If you're new, start with something user-friendly.

Evaluating Project Requirements: Choosing the Right Saw Swing Size

Choosing the right saw swing size can significantly impact your project’s efficiency. Different projects require different swing sizes. A standard size might be sufficient for small woodworking tasks, while larger cuts call for a bigger swing. According to industry reports, selecting the correct size can reduce cutting time by up to 30%.

Tips: Always assess the dimensions of your workpiece. Measure twice before making a decision. A larger swing provides more versatility. However, it can also be cumbersome in tight spaces. If you're working in a small shop, consider how the saw's size will fit your environment.

Think about future needs too. Investing in a saw with a larger swing may be wise if you plan to tackle larger projects. Yet, remember that the saw's weight and size can affect maneuverability. Some users report difficulty in handling larger saws effectively, leading to potential safety hazards. Reflect on your past experiences with saws and weigh your options carefully.

How to Choose the Right Saw Swing for Your Projects? - Evaluating Project Requirements: Choosing the Right Saw Swing Size

| Project Type | Recommended Saw Swing Size | Material Type | Precision Requirement | Safety Features |

|---|---|---|---|---|

| Furniture Making | Small (0-10 inches) | Softwood, Hardwood | High | Anti-kickback, Blade Guard |

| Construction | Medium (10-15 inches) | Plywood, OSB | Medium | Electric brake, Safety switch |

| Craft Projects | Small (0-10 inches) | Cardboard, Foam | Low | Lightweight design, Easy handling |

| Woodworking | Large (15+ inches) | Hardwood, Softwood | Very High | Blade guard, Dust extraction |

| Metal Fabrication | Medium (10-15 inches) | Aluminum, Steel | High | Emergency stop, Low vibration |

Assessing Blade and Motor Specifications for Optimal Performance

Choosing the right saw swing for your project involves a deep dive into blade and motor specifications. The blade's size and type play a crucial role in performance. For instance, a larger blade can cut through thicker materials. However, it might require a more powerful motor. If you go for a lighter motor, the larger blade may not achieve its best performance. This can lead to frustration during your projects.

Motor specifications also matter significantly. A motor with higher RPM can deliver faster cuts. However, this speed can compromise control, especially for intricate work. You need to find a balance. Consider the materials you'll work with. Hardwoods require a different approach than softwoods. The wrong choice can lead to dull blades and wasted time.

Don't overlook the importance of the saw's swing. A saw with limited swing may restrict your cutting angles. This limitation can be frustrating when you want precise cuts. Before making your decision, reflect on your specific needs. Do you prioritize speed, or is detail more important? The right combination of blade and motor will enhance your overall experience.

Safety Considerations When Selecting a Saw Swing for Your Workshop

When selecting a saw swing, safety should be your top priority. Consider the workspace layout. A cluttered area can lead to accidents. Ensure there's enough clearance around the saw. This allows for ease of movement and reduces risks. Position the saw swing near power outlets, but keep cords organized. Trip hazards are a common cause of injuries.

Look at the blade guard features. They are essential for protecting you. A well-designed guard can prevent accidental cuts. Regularly check it for wear and tear. Inspecting your equipment can be tedious but is crucial. Don’t overlook the importance of wearing personal protective gear. Gloves and safety glasses are a must.

It’s easy to underestimate the risks involved. Reflect on your previous experiences with saw swings. Have you ever felt that moment of panic? Safety should never be taken lightly. Each time you use a saw swing, stay alert. Take breaks to avoid fatigue. Returning to your project focused can prevent dangerous mistakes.

Maintenance Tips for Your Chosen Saw Swing to Ensure Longevity

Maintaining your saw swing is crucial for ensuring it lasts long and performs effectively. Regular care can prevent issues that arise from wear and tear. Simple practices can extend its life and maintain its accuracy.

To start, keep your saw swing clean. Dust and debris can affect its operation. Use a brush or compressed air to remove particles from moving parts. This small effort can prevent larger problems down the line. Checking the blade regularly is essential too. A dull blade can strain the motor, leading to unnecessary repairs.

Lubrication is another key factor. Applying oil to pivot points can reduce friction. This makes for smoother operation and minimizes wear. Make sure to wipe away excess oil to avoid attracting dirt. Finally, periodically inspect all cables and wires. Signs of wear can lead to more significant malfunctions. Address any fraying immediately to avoid further issues.

Remember, neglecting your saw swing can result in unexpected downtime. Daily checks might seem tedious, but they will save you time and money later. The goal is a well-maintained tool that consistently performs well on your projects.