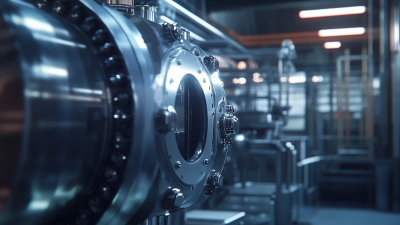

Essential Checklist for Choosing the Right Hot Isostatic Pressing Machine for Your Manufacturing Needs

The global market for Hot Isostatic Pressing Machines is experiencing significant growth, driven by the increasing demand for high-performance materials in industries such as aerospace, automotive, and medical. According to a recent report by MarketsandMarkets, the hot isostatic pressing market is projected to reach $1.5 billion by 2025, expanding at a compound annual growth rate (CAGR) of 5.8%. This surge highlights the critical role that Hot Isostatic Pressing Machines play in enhancing material properties through the elimination of porosity, improving mechanical strength, and achieving uniformity in high-performance components. As manufacturers face the challenge of selecting the right equipment tailored to their specific needs, understanding the essential criteria for comparison becomes paramount. This blog aims to present a comprehensive checklist to guide decision-makers in choosing the optimal Hot Isostatic Pressing Machine that not only meets their manufacturing requirements but also aligns with industry standards and technological advancements.

Key Factors to Consider When Selecting a Hot Isostatic Pressing Machine

When selecting a Hot Isostatic Pressing (HIP) machine, several key factors should be taken into account to ensure it meets specific manufacturing needs. One crucial element is the operational temperature and pressure capabilities of the machine. For instance, recent advancements have demonstrated that pressing at high temperatures, such as 1280°C, resulted in a more homogeneous grain structure, significantly enhancing the creep performance and corrosion resistance of materials like CM247LC alloy. Additionally, optimizing parameters such as pressure is essential; studies have shown that using lower pressures can effectively laminate carbon films onto perovskite devices, which is critical for the production of efficient solar cells.

Another factor to consider is the compatibility of the HIP machine with the desired materials and their microstructural requirements. The examination of different powder sizes used in the processing of Ti-6Al-4V alloys indicates that the particle size directly influences sintering outcomes and, ultimately, mechanical properties. As the additive manufacturing sector continues to expand, innovative designs and features in HIP systems, such as enhanced work zone sizes, are becoming increasingly important to accommodate various production demands. By focusing on these key factors, manufacturers can select the right HIP machine to optimize material performance and achieve desired outcomes in their applications.

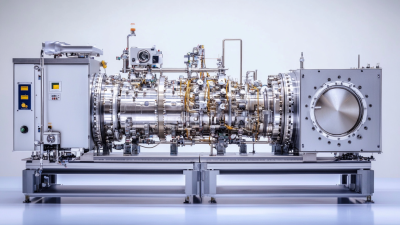

Understanding Different Types of Hot Isostatic Pressing Technologies

When selecting a hot isostatic pressing (HIP) machine, understanding the various technologies available is paramount to meeting your manufacturing needs. There are primarily two types of HIP technologies: gas and liquid. Gas HIP uses an inert gas, typically argon, which allows for uniform pressure distribution and is ideal for materials that need to maintain high dimensional accuracy. On the other hand, liquid HIP employs a hydraulic fluid, which can achieve higher pressures, making it suitable for more complex geometries or those requiring significant densification.

Tip: Evaluate the material properties of the components you plan to process. Some materials are better suited for gas HIP due to their thermal sensitivity, while others might benefit from the additional compressive forces of liquid HIP.

Moreover, the choice of technology can impact the cycle time and efficiency of your processes. While gas HIP systems may be slower due to gradual heating and pressure application, liquid systems can often reduce cycle times significantly. Therefore, it's important to consider not just the technology, but also your production timelines when making your decision.

Tip: Analyze the production volume you expect. For high-volume manufacturing, a liquid HIP might offer better throughput, whereas gas HIP might be more beneficial for small-batch production where precision is critical.

Evaluating Material Compatibility for Your Pressing Needs

When selecting a hot isostatic pressing (HIP) machine, evaluating material compatibility is critical to ensure optimal performance and product quality. According to a recent report by Grand View Research, the global HIP equipment market is projected to reach $2.63 billion by 2026, reflecting the growing demand across industries like aerospace, automotive, and medical. The choice of materials used in the pressing process greatly influences not only the efficiency of the machine but also the properties of the final product.

Different materials possess distinct thermal and mechanical properties, which can impact how they behave under the high temperature and pressure conditions typical of HIP. For instance, while titanium and its alloys are well-known for their superior strength-to-weight ratio and excellent biocompatibility, they require precise temperature control to avoid deformation during pressing. A study published in the Journal of Materials Processing Technology highlights that improper material selection can lead to up to a 30% reduction in yield strength, emphasizing the necessity of a careful evaluation of material properties, including thermal conductivity and expansion rates. Ensuring that the HIP machine is compatible with the selected materials will not only enhance product performance but also reduce production costs associated with waste and rework.

Material Compatibility Evaluation for Hot Isostatic Pressing Machines

Assessing Production Capacity and Efficiency Requirements

When selecting the right hot isostatic pressing (HIP) machine, evaluating production capacity and efficiency requirements is crucial. According to recent industry studies, the effectiveness of your HIP application can significantly impact production scalability. For instance, a report analyzing the hydrogen production capabilities at an industrial scale noted efficiencies of around 90% when utilizing advanced electrolysis methods. Such insights suggest that manufacturers should not only consider the current output but also the potential for future scalability and energy consumption patterns associated with their operations.

Additionally, the ongoing shift towards sustainable practices is reshaping the landscape for production machinery. With the rise of techno-economic assessments for technologies like green hydrogen production integrated with hybrid systems, it's important to align the choice of HIP machinery with broader environmental goals. Recent evaluations indicate that hydrogen production methods, such as those using biomass or renewable energy sources, can enhance efficiency and reduce carbon footprints. Thus, manufacturers are urged to assess how their HIP machines can adapt to these evolving energy landscapes, ensuring that they meet both current operational needs and future sustainability targets.

Essential Checklist for Choosing the Right Hot Isostatic Pressing Machine for Your Manufacturing Needs

| Feature | Description | Importance Level | Recommended Capacity Range |

|---|---|---|---|

| Production Capacity | Assess the machine's ability to handle required volume and production speed | High | 100 kg - 5000 kg |

| Temperature Range | Temperature capabilities for specific materials | Medium | 100°C - 2000°C |

| Pressure Capabilities | Maximum pressure the machine can apply | High | 1000 MPa - 3000 MPa |

| Cycle Time | Time required for pressing cycles | Medium | 30 min - 90 min |

| Automation Level | Degree of automation for ease of use | High | Fully automated / Semi-automated |

| Safety Features | Built-in features to ensure operator safety | Very High | N/A |

Cost-Benefit Analysis: Balancing Investment with Output Quality

When selecting a hot isostatic pressing (HIP) machine, the cost-benefit analysis plays a pivotal role in determining the best fit for your manufacturing needs. It's essential to evaluate not just the upfront costs of different machines, but also the long-term benefits they can deliver. Higher quality output can often justify a larger initial investment, particularly for industries where precision and material integrity are critical. Machines that promise consistent and superior results reduce the risk of rework and scrap, translating into significant savings over time.

Additionally, consider the operational efficiency and maintenance requirements of the HIP machine. A machine that operates with minimal downtime and lower energy consumption can significantly enhance productivity, leading to a better return on investment. Assessing the lifecycle costs, including maintenance, training, and potential upgrades, gives a clearer picture of how the investment can pay off in the long run. Ultimately, a well-rounded understanding of both costs and benefits ensures that your choice not only meets current manufacturing demands but also positions your company for future growth and success.

Related Posts

-

Innovative Solutions for Hip Isostatic Pressing Efficiency

-

Unlocking the Potential of Cladding Hot Isostatic Pressing for Superior Material Performance

-

2025年热等静压与增材制造的创新之路完整指南

-

Complete Guide to Understanding the Hot Isostatic Pressing Process for Global Manufacturers

-

Comprehensive Insights into Hot Isostatic Pressing Additive Manufacturing for Global Buyers

-

Mastering Hip Isostatic Pressing: A Step-by-Step Guide for Industry Professionals