Understanding the Challenges in Achieving the Best Isostatic Pressing Solutions

In the realm of advanced manufacturing, Isostatic Pressing has emerged as a pivotal technique for enhancing material properties and achieving uniform density in various components. However, navigating the complexities associated with this process presents a unique set of challenges that manufacturers must address to realize the full potential of Isostatic Pressing solutions. This blog aims to delve into those challenges, highlighting examples of common hurdles encountered in the industry, such as the intricacies of pressure distribution, material selection, and equipment calibration. By exploring these issues, we can gain a deeper understanding of how to optimize Isostatic Pressing processes, ultimately leading to improved product quality and operational efficiency in various applications.

In the realm of advanced manufacturing, Isostatic Pressing has emerged as a pivotal technique for enhancing material properties and achieving uniform density in various components. However, navigating the complexities associated with this process presents a unique set of challenges that manufacturers must address to realize the full potential of Isostatic Pressing solutions. This blog aims to delve into those challenges, highlighting examples of common hurdles encountered in the industry, such as the intricacies of pressure distribution, material selection, and equipment calibration. By exploring these issues, we can gain a deeper understanding of how to optimize Isostatic Pressing processes, ultimately leading to improved product quality and operational efficiency in various applications.

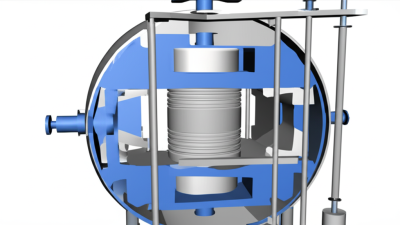

Exploring Isostatic Pressing: Definition and Key Applications in Manufacturing

Isostatic pressing is a shaping technique extensively used in the manufacturing of materials, particularly ceramics and metals. This method applies uniform pressure from all sides, resulting in a uniform density and improved material properties. According to a report by Grand View Research, the global market for isostatic pressing is expected to reach $6.10 billion by 2025, driven by its crucial role in high-performance applications such as aerospace and automotive sectors. The ability to produce components with complex geometries and enhanced mechanical properties makes isostatic pressing an indispensable process for manufacturers aiming for innovation and efficiency.

When implementing isostatic pressing, manufacturers should consider some key tips to optimize their processes. First, ensure that raw materials are of high quality, as the characteristics of the final product heavily rely on input materials. Additionally, maintaining precise control over the pressure and temperature during the pressing cycle can significantly influence the end product's properties. Finally, regular maintenance of the pressing equipment can prevent costly downtime and ensure consistent performance throughout production.

As industries rapidly evolve, understanding the key applications of isostatic pressing becomes increasingly important. Key sectors such as electronics, where demand for high-performance materials is on the rise, significantly benefit from the unique advantages offered by isostatic pressing techniques. By integrating this method, manufacturers can achieve the superior quality and functionality required for next-generation products, solidifying their position in a competitive market.

Identifying Common Challenges in Isostatic Pressing Techniques

Isostatic pressing is a widely utilized technique in manufacturing that ensures uniform density and improved mechanical properties in materials. However, the process is not without its challenges. One of the primary issues faced by manufacturers is the inconsistency in pressure distribution.

According to a report by the International Journal of Advanced Manufacturing Technology, variations in pressure can lead to defects in the final product, adversely affecting its performance. This inconsistency often stems from the uneven characteristics of the tooling and the raw materials used, highlighting the need for rigorous quality control measures.

Another significant challenge is the cost associated with achieving optimal isostatic pressing conditions. A study by the American Ceramic Society noted that while isostatic pressing enhances product quality, the initial investment in specialized equipment can be substantial.

Furthermore, the operational costs linked to maintaining high precision in pressure application can escalate quickly, putting financial strain on manufacturers. These challenges necessitate a deeper understanding of the material behavior during the pressing process and the implementation of advanced technologies to minimize variability and enhance efficiency.

Innovations in Isostatic Pressing: Advancements Driving Efficiency

Innovations in isostatic pressing are revolutionizing the manufacturing landscape, driving efficiency and unlocking new possibilities in material science. As industries strive to enhance product quality and reduce waste, advancements in technology are paving the way for more precise and uniform pressure applications. This has led to the development of advanced equipment that not only minimizes energy consumption but also optimizes production cycles. New automation capabilities are also being integrated into the process, allowing for real-time monitoring and adjustments to ensure consistency and reduce human error.

Moreover, the use of cutting-edge materials and techniques is transforming the isostatic pressing landscape. Options such as high-temperature and high-pressure capabilities enable manufacturers to work with a broader range of materials, including ceramics and composites, which are becoming increasingly popular in aerospace and automotive applications. These innovations not only enhance the properties of the finished products but also contribute to a more sustainable manufacturing process, with a focus on recycling and reducing the carbon footprint. As the industry embraces these advancements, the journey toward achieving the best isostatic pressing solutions is marked by a commitment to continuous improvement and innovation.

Quality Control in Isostatic Pressing: Ensuring Optimal Production Standards

Quality control in isostatic pressing is paramount to achieving optimal production standards across various industries, including ceramics, aerospace, and biomedical manufacturing. According to a report by the International Journal of Advanced Manufacturing Technology, defects in isostatically pressed components can lead to a staggering decrease in performance, with studies showing up to a 40% failure rate in critical applications due to inadequate quality processes. This highlights the necessity for stringent quality assurance measures throughout the production cycle.

To ensure quality control, manufacturers should focus on the monitoring of key parameters such as temperature, pressure, and time during the pressing process. Implementing real-time data analysis can help in identifying anomalies early on. **Tip: Regular calibration of equipment is essential to maintain accuracy and reliability in measurements, which directly affects the quality of the final product.**

Furthermore, establishing a robust feedback loop from the end-users can provide critical insights for continuous improvement. It enables manufacturers to adapt to the evolving requirements of various sectors. **Tip: Engaging in frequent training for operators helps bolster their understanding of the quality control processes, fostering a culture of excellence and reducing production errors significantly.**

Understanding the Challenges in Achieving the Best Isostatic Pressing Solutions

This chart illustrates the frequency of common quality control challenges faced in isostatic pressing across different materials.

Global Competitiveness: China’s Role in the Isostatic Pressing Market

The isostatic pressing market is undergoing significant transformation, with China emerging as a pivotal player in this global landscape. With a projected market growth, estimated at a compound annual growth rate (CAGR) of 6.1% from 2025 to 2034, the need for innovative solutions in powder metallurgy becomes more pressing. China's advancements in technology and manufacturing capabilities enable it to offer competitive isostatic pressing solutions that cater to diverse industrial needs.

China's continuous investment in research and development in the field of isostatic pressing has positioned the country as a leader in this market. As global demand for high-performance materials grows, China's role in providing efficient and cost-effective isostatic pressing technologies becomes increasingly vital. The burgeoning market, valued at approximately USD 7.8 billion in 2024, reflects the rising trends in various industries that rely on isostatic pressing techniques to enhance product quality and performance.