7 Best Practices for Success in Hip Sintering Technology

In recent years, the demand for advanced materials has led to significant advancements in manufacturing technologies, particularly in the realm of Hip Sintering. This process, which utilizes hot isostatic pressing (HIP) to produce highly dense materials, represents a critical innovation in industries like aerospace and biomedical engineering. According to a report by MarketsandMarkets, the global market for Hip Sintering technology is projected to grow from USD 1.2 billion in 2020 to USD 2.3 billion by 2025, highlighting the increasing reliance on this method for achieving superior material properties. As manufacturers seek to optimize performance while reducing costs, implementing best practices in Hip Sintering has become essential.

This blog will explore the seven best practices that can enhance success in Hip Sintering technology, ensuring better quality, efficiency, and competitiveness in the evolving manufacturing landscape.

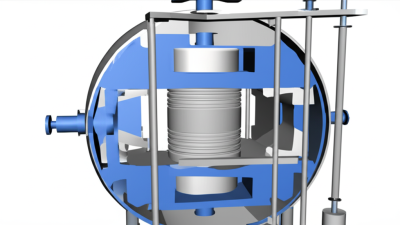

Understanding the Fundamentals of Hip Sintering Technology

Hot Isostatic Pressing (HIP) sintering technology has become a vital process in the manufacturing of high-performance materials, especially in industries such as aerospace and automotive. At its core, HIP sintering involves applying high temperature and pressure uniformly to powder materials, resulting in dense and homogenous components. According to a report by ResearchAndMarkets, the global HIP market is projected to reach $575 million by 2026, reflecting an annual growth rate of 6.2%. This growth is driven by the increasing demand for lightweight and strong materials that can withstand extreme conditions.

Understanding the fundamentals of HIP sintering technology is crucial for manufacturers aiming to optimize production efficiency and material properties. Key parameters include temperature, pressure, and dwell time, which significantly influence the microstructure and mechanical properties of the final product. For instance, a study published in the Journal of Materials Science demonstrated that optimizing these parameters can improve the tensile strength of materials by up to 30%. As the industry continues to evolve, maintaining a strong grasp of these fundamentals will empower manufacturers to innovate and enhance their competitive edge in the market.

Key Parameters Influencing Success in Hip Sintering Processes

Hip sintering technology, or hot isostatic pressing, relies heavily on specific key parameters that greatly influence its success. The control of temperature is pivotal; reaching and maintaining the optimal temperature allows for effective diffusion and densification of materials. A temperature that is too low can lead to insufficient bonding, while excessive heat may cause unwanted reactions or degradation of the material. Therefore, precise temperature management is essential for achieving high-quality sintered components.

Another critical parameter is the pressure applied during the sintering process. The right pressure ensures that the material is compacted uniformly, reducing porosity and enhancing mechanical properties. Moreover, the duration of the sintering cycle must also be carefully calibrated. Insufficient time can result in incomplete sintering, while excessive durations can lead to grain growth and weakening of the final product. By meticulously adjusting these parameters, manufacturers can optimize their hip sintering processes, ultimately yielding superior materials with enhanced performance characteristics.

7 Best Practices for Success in Hip Sintering Technology - Key Parameters Influencing Success in Hip Sintering Processes

| Parameter | Description | Optimal Range |

|---|---|---|

| Temperature | Critical for achieving densification and material properties. | 1200-1400 °C |

| Pressure | Influences the density and microstructure of the sintered material. | 30-100 MPa |

| Sintering Time | Length of time at temperature affects grain growth and porosity. | 1-4 hours |

| Atmosphere | Presence of gases can affect oxidation and reduction reactions. | Inert atmosphere preferred |

| Powder Characteristics | Particle size, shape, and distribution influence packing density. | < 20 microns |

| Heating Rate | Rate of temperature increase can affect microstructure evolution. | 1-10 °C/min |

| Cooling Rate | Rapid cooling can lead to thermal stresses and cracks. | Controlled cooling required |

Optimizing Material Selection for Enhanced Sintering Outcomes

Material selection is a critical factor in achieving optimal outcomes in hip sintering technology. One of the primary considerations is the properties of the powders being used. High-quality powders with uniform particle size and shape can significantly enhance densification during the sintering process. This uniformity reduces the porosity of the final product and improves mechanical properties. Additionally, incorporating additives such as binders or sintering aids can facilitate the process, leading to better performance characteristics in the final sintered component.

Another vital aspect of material selection is understanding the compatibility of different materials. This includes not just the primary material, but also any coatings, fillers, or reinforcements that may be introduced to enhance performance. A well-chosen combination can result in superior sintering behavior and enhanced durability at elevated temperatures. Furthermore, considerations around the thermal and chemical stability of the materials during the sintering phase can prevent issues such as phase changes or degradation, securing a robust final product that meets industry standards. Ultimately, careful selection of these materials based on their characteristics and their interactions in the sintering environment is essential for success in hip sintering technology.

Implementing Quality Control Measures in Hip Sintering

Implementing quality control measures in hot isostatic pressing (HIP) sintering is crucial for ensuring the desired properties and performance of materials produced through this advanced manufacturing technique. First and foremost, developing a robust material characterization process is essential. This involves thorough analysis of the raw materials to verify their quality before they enter the HIP process. Utilizing techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) can provide insights into the microstructure and phase composition of the materials, helping in the anticipation of potential issues during sintering.

Moreover, stringent monitoring of the sintering process parameters—such as temperature, pressure, and time—plays a vital role in maintaining quality. Real-time data collection and analysis can help identify deviations from established protocols, enabling timely adjustments to mitigate defects. In addition, implementing a comprehensive post-sintering inspection regimen, including non-destructive testing methods, ensures that the final products meet stringent industry standards.

By prioritizing quality control at every stage of the HIP sintering process, manufacturers can significantly enhance their production consistency and reliability, leading to superior performance in the end-use applications.

Innovative Techniques to Improve Efficiency and Scalability in Sintering

Innovative techniques in hip sintering technology are becoming increasingly important as industries strive for greater efficiency and scalability. The global magnesium market, projected to reach a value of $9.326 billion by 2025, reflects the growing demand for advanced materials and processes that optimize production capabilities. With a compound annual growth rate of 1.4% forecasted until 2033, the need for innovative sintering methods is more critical than ever.

Recent advancements in continuous laser-assisted 3D printing technology highlight notable efficiency improvements, particularly in material handling, allowing for a higher viscosity of up to 3000 times without clogging, thereby enhancing production rates. Moreover, the integration of smart manufacturing solutions within the steel industry points towards a transformative shift aimed at sustainability and reduced environmental impact. As manufacturers adopt these innovative techniques, they not only boost operational scalability but also align with emerging trends in green technology—a crucial factor for maintaining competitiveness in a rapidly evolving market landscape.

Efficiency and Scalability in Hip Sintering Technology

This chart displays the best practices for success in Hip Sintering Technology, emphasizing innovative techniques aimed at improving both efficiency and scalability in the sintering process.

Related Posts

-

Exploring Innovative Alternatives in Hip Isostatic Pressing: Trends Shaping 2025 and Beyond

-

5 Reasons Why Best Cold Isostatic Compaction is Key to Achieving 90 Percent Material Efficiency

-

Understanding the Challenges in Achieving the Best Isostatic Pressing Solutions

-

7 Best Practices for Optimizing the Hot Isostatic Pressing Process in Manufacturing

-

Maximizing Efficiency and Reducing Downtime with Isostatic Pressing Machine Maintenance Strategies

-

Innovative Solutions for Hip Isostatic Pressing Efficiency