Exploring Applications and Unique Features of the Best Cold Isostatic Compaction Techniques in Industry

Cold Isostatic Compaction (CIC) is rapidly gaining traction in various industrial applications due to its unique ability to produce high-density materials with uniform properties. According to a recent report by MarketsandMarkets, the global isostatic pressing market is projected to grow from $2.21 billion in 2020 to $3.12 billion by 2026, showcasing the increasing significance of techniques like CIC in sectors such as aerospace, automotive, and electronics. This method enables manufacturers to achieve exceptional material performance while also reducing production waste, aligning with sustainable manufacturing goals. As industries strive for product reliability and performance efficiency, understanding the unique features and diverse applications of cold isostatic compaction becomes essential in optimizing operational workflows and enhancing product innovation. In this blog, we will explore these applications, the advantages offered by CIC, and the reasons behind its growing adoption across various sectors.

Understanding Cold Isostatic Compaction: Definition and Importance in Manufacturing

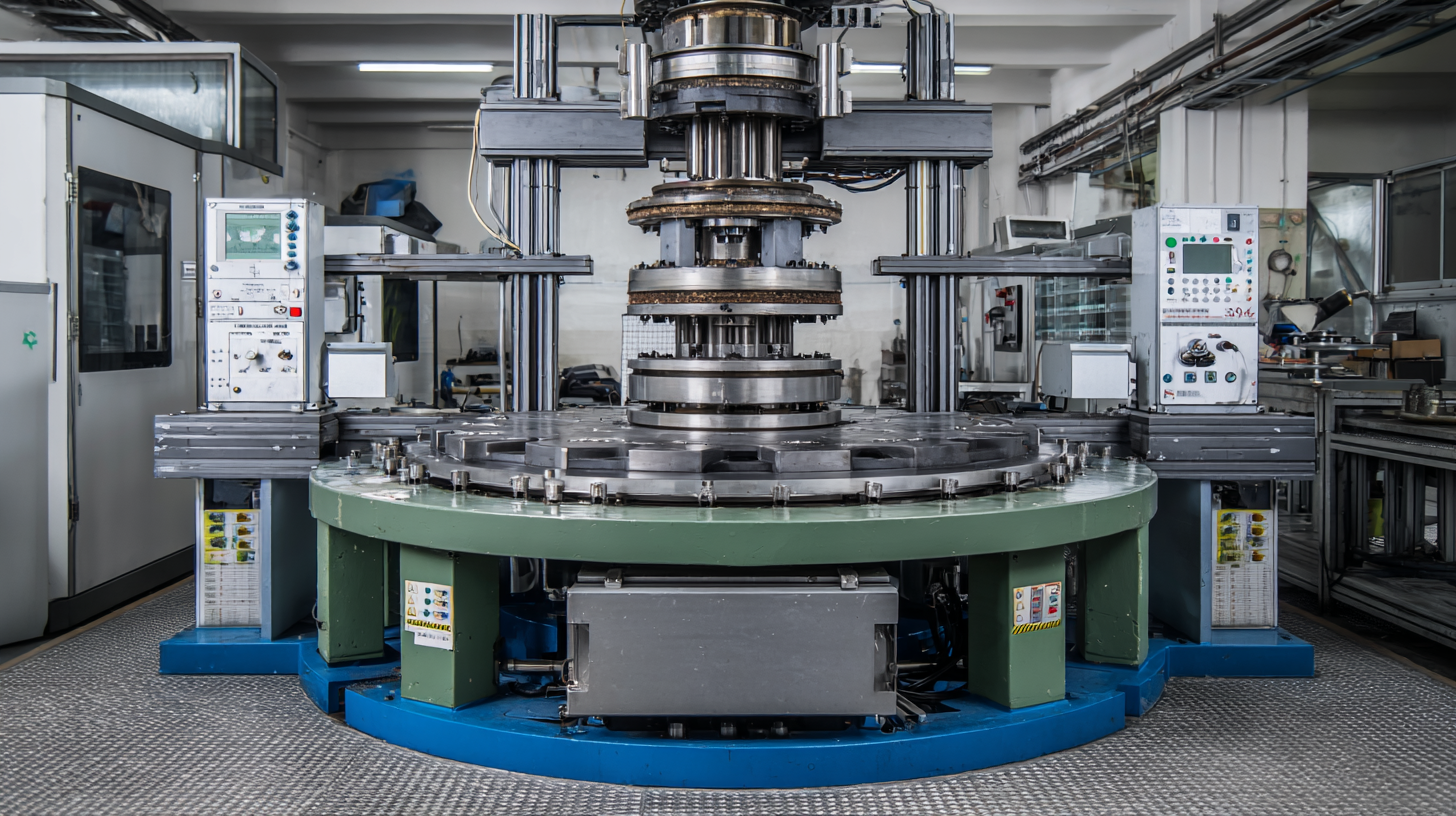

Cold Isostatic Compaction (CIC) is a sophisticated technique in the manufacturing sector that enhances the density and strength of materials without subjecting them to high temperatures. This method utilizes hydraulic pressure to uniformly apply force around a molded material, promoting an isotropic structure that is essential for the mechanical properties of various products. Industry reports suggest that this technology is increasingly preferred in sectors such as ceramics, metal powders, and advanced composites, where precision and durability are paramount. According to a report by MarketsandMarkets, the global cold isostatic pressing market is projected to reach USD 1.95 billion by 2025, driven by the demand for high-performance materials.

The importance of CIC lies in its ability to improve material performance while minimizing production defects. Research indicates that materials processed through cold isostatic compaction can achieve density levels exceeding 98%, significantly enhancing product reliability. Furthermore, a study published in the Journal of Manufacturing Science and Engineering highlights that components made via CIC exhibit superior mechanical properties, with tensile strength improvements of up to 30% compared to those made using traditional powder metallurgy techniques. This makes cold isostatic compaction an invaluable process in manufacturing high-quality components across various industries.

Key Techniques in Cold Isostatic Compaction: Methods and Mechanisms Explained

Cold Isostatic Compaction (CIP) has emerged as a pivotal technology in the manufacturing sector, particularly due to its unique ability to create uniform density in materials. Among the key techniques involved in CIP are pressure application and temperature control, which play crucial roles in ensuring optimal compaction. Recent advancements in response surface optimization and finite element simulation have highlighted the effectiveness of CIP in preparing microporous carbon refractories. Unlike traditional die compression methods, using cold isostatic pressing allows for a more consistent and refined formation of carbon blocks, thereby enhancing overall material performance.

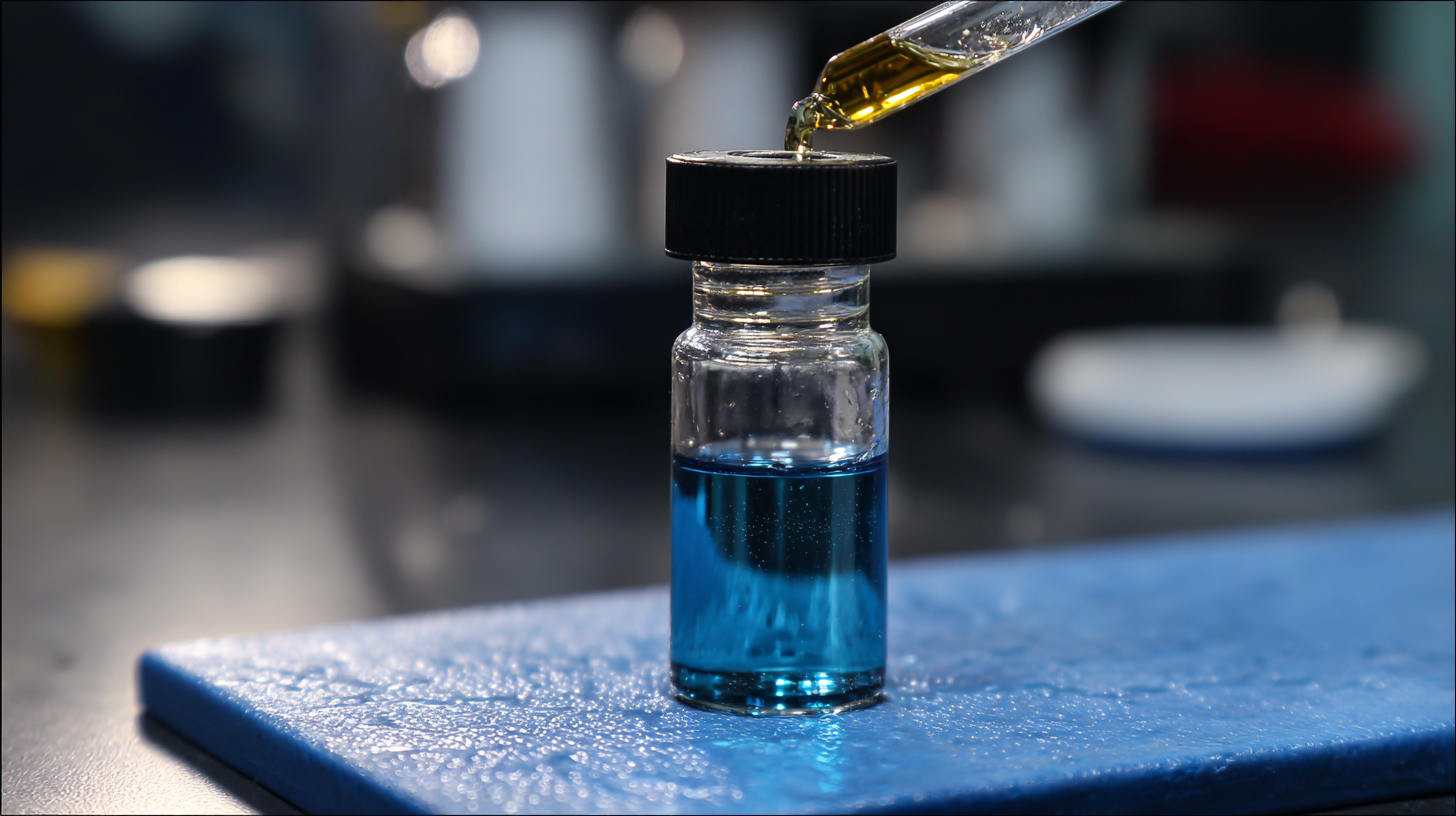

When considering the mechanisms behind successful cold isostatic compaction, it’s essential to focus on the self-consolidation strategy. This simplified method proves advantageous when preparing materials such as Li7La3Zr2O12 solid electrolytes, offering a streamlined approach compared to conventional techniques. By optimizing factors such as pressure and compaction time, manufacturers can achieve superior results with this method.

**Tip:** When implementing CIP in your processes, ensure to conduct thorough simulations to predict material behavior under various conditions. This preemptive analysis can save time and resources, leading to more efficient manufacturing practices. Additionally, consider experimenting with different material compositions to fully leverage the advantages of cold isostatic pressing.

Industry Applications of Cold Isostatic Compaction: From Aerospace to Medical Devices

Cold Isostatic Compaction (CIC) has become an essential technique across various industries, significantly enhancing the production and performance of critical components. In aerospace, for example, CIC is employed to create high-density components from advanced materials, which are crucial for reducing weight and improving fuel efficiency. According to a report by Deloitte, the aerospace industry is projected to grow at a rate of 3.5% annually, with the demand for lighter and stronger materials catalyzing the adoption of CIC technologies.

The medical device sector is another area where cold isostatic compaction is gaining traction. CIC allows for the precise manufacturing of components like prosthetics and implants, which require stringent quality controls and reliability. A study published in the Journal of Biomedical Materials Research highlights that components produced through CIC show superior mechanical properties, leading to a 20% increase in lifespan compared to traditionally manufactured parts. As the global medical device market is expected to reach $612 billion by 2025, the role of CIC in ensuring high-performance products is becoming increasingly vital.

Evaluating the Benefits of Cold Isostatic Compaction for Material Properties and Performance

Cold Isostatic Compaction (CIC) has emerged as a transformative technique in the material processing industry, offering distinct advantages in enhancing material properties and performance. By applying uniform pressure from all directions, CIC enables the densification of powders, leading to improved mechanical characteristics. This process not only reduces porosity but also enhances the material's structural integrity, making it suitable for demanding applications in aerospace, automotive, and electronics sectors.

The benefits of CIC extend beyond just density improvement. The technique allows for the processing of complex geometries and materials that may otherwise be challenging to compact using traditional methods. This flexibility opens up new possibilities for innovation in material design. Additionally, the absence of high-temperature processes in CIC helps preserve the material's original properties, leading to better performance and longevity in application. Ultimately, the advantages of Cold Isostatic Compaction are pivotal in advancing material science, facilitating the development of more efficient, durable, and high-performing components across various industries.

Comparative Analysis of Cold Isostatic Compaction vs. Traditional Compaction Methods

Cold Isostatic Compaction (CIC) has emerged as a leading technique in material processing, particularly when compared to traditional compaction methods. By applying equal pressure from all directions, CIC effectively eliminates voids within the material, leading to a more uniform density and enhanced mechanical properties. This method offers a significant advantage over traditional compaction, which typically relies on unidirectional force. As a result, traditional methods can introduce inconsistencies and stress concentrations that negatively affect the final product’s performance.

Moreover, the versatility of cold isostatic compaction makes it suitable for a variety of materials, including complex shapes and fragile composites that might not withstand the rigorous conditions of conventional methods. In contrast, traditional compaction often requires additional processing steps, such as sintering, to achieve density requirements, which can be time-consuming and costly. The efficiency of CIC not only reduces production times but also minimizes material waste, making it a more economical choice for manufacturers looking to enhance their production processes while maintaining high quality standards.