2026 Best Ball Bearings for High Performance Applications?

In the world of high-performance applications, the importance of Ball Bearings cannot be overstated. According to Dr. Emily Thompson, a renowned expert in mechanical engineering, “The right ball bearing can significantly enhance efficiency and performance.” Companies striving for excellence must carefully select their ball bearings to meet demanding standards.

Ball bearings operate under extreme conditions. Their design often determines the success or failure of machinery. Modern ball bearings must balance durability with lightweight materials. Innovations in this field can lead to breakthroughs in various sectors, from aerospace to automotive.

However, not every product lives up to expectations. Many overlook crucial details like inner race surface finish. This can lead to premature failure of the ball bearing. The pursuit of optimal performance in these applications requires ongoing reevaluation and improvement.

Understanding the Importance of Ball Bearings in High Performance Applications

Ball bearings play a critical role in high-performance applications. They reduce friction and support loads in various machinery. A well-designed bearing enhances efficiency and durability. In many cases, subpar bearings lead to failures. This can be costly in terms of repairs and downtime.

Understanding materials is essential. Different environments require different materials. For instance, corrosion-resistant materials work well in harsh conditions. However, they may not always provide the best load-carrying capacity. Designers face challenges when selecting the right bearing.

Maintenance is another vital aspect. Regular checks can prevent unexpected failures. Often, users neglect this routine, leading to problems. Over time, lubrication degrades and debris accumulates. These issues can compromise performance. A proactive approach is necessary to ensure long-lasting functionality.

Types of Ball Bearings Used in High Performance Environments

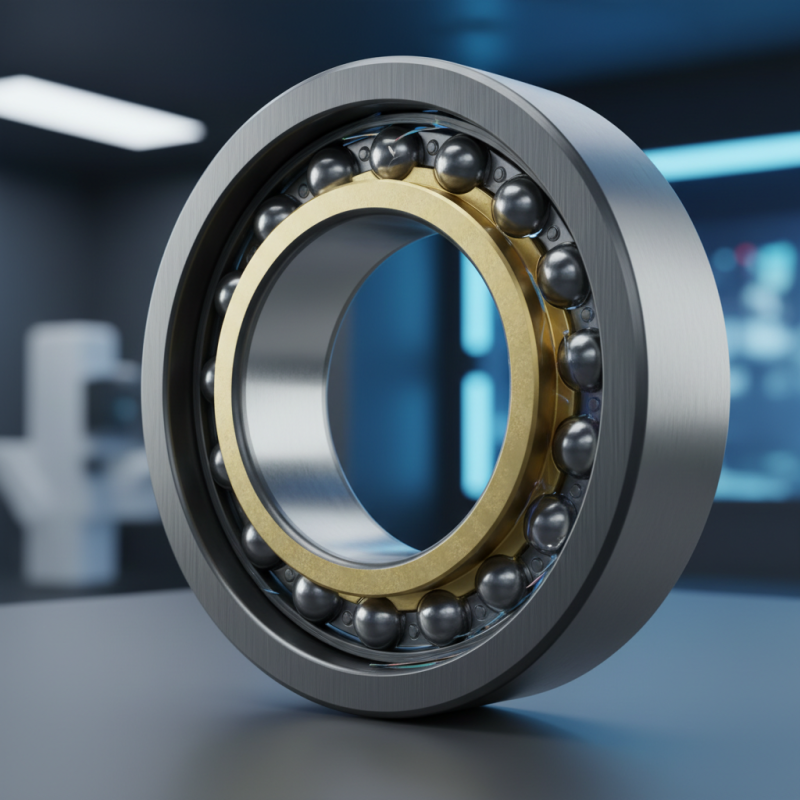

When discussing ball bearings for high-performance environments, several types stand out. Deep groove ball bearings offer versatility and are widely used. Their design accommodates both radial and axial loads, making them ideal in varied applications. These bearings are durable and can operate at high speeds, yet they may not excel under shock loads.

Another option is angular contact ball bearings. These are preferred for applications requiring high precision. They support higher axial loads than deep groove bearings. However, the complexity of their design may increase maintenance demands. Their performance during extreme conditions is notable but sometimes requires careful selection to avoid failure.

Lastly, ceramic hybrid ball bearings provide lightweight and corrosion-resistant alternatives. They excel in high-speed applications, proving beneficial in aerospace and motorsports. Yet, their cost can be a limiting factor. Buyers must consider the specific needs of their application to ensure the best choices are made. Understanding these nuances is essential for optimizing performance while acknowledging the potential drawbacks of each bearing type.

Key Factors Influencing the Performance of Ball Bearings

When it comes to high-performance applications, several factors influence the effectiveness of ball bearings. One crucial element is the material used. Steel, ceramic, and composite materials each have unique qualities. Steel is durable but heavier. Ceramics offer lightweight benefits but can be brittle. Understanding these materials helps engineers choose the right one.

Another critical factor is lubrication. The type and method of lubrication can greatly affect performance. Proper lubrication reduces friction and prevents overheating. However, choosing the wrong lubricant can lead to problems. Over time, this can cause wear or even failure. Regular maintenance is essential to ensure optimal performance.

Finally, the design and precision of the ball bearings play a significant role. Tolerances must be tight to avoid excessive play. Variations in design can lead to inefficiencies. Engineers must consider load capacity and speed rating. Each decision dims the possibility of achieving maximum performance. It's a delicate balance that requires careful thought and ongoing evaluation.

Top Manufacturers of High Performance Ball Bearings

High performance ball bearings play a crucial role in various industries. They are essential for reducing friction and enhancing efficiency. Selecting the right manufacturer is vital for optimal results.

Top manufacturers focus on advanced materials and innovative designs. Many use ceramic or hybrid materials for improved durability. According to a recent market report, the ball bearing market is expected to grow significantly. By 2026, the demand for high-performance variants is projected to rise by 6.4% annually.

Tips: When choosing ball bearings, consider factors like load capacities and speed ratings. Look for manufacturers that offer detailed specifications. Inconsistent quality can lead to unexpected failures. Always check for industry certifications, which ensure adherence to standards.

Remember that not all ball bearings are created equal. The right choice can greatly impact machinery performance. Engineers often face challenges in balancing cost and quality. This makes testing essential. Regular evaluations can help in identifying potential improvements.

Future Trends in Ball Bearing Technology for Enhanced Performance

The future of ball bearing technology is promising, with trends leaning towards enhanced performance and durability. According to a recent industry report, the global ball bearing market is expected to grow by over 7% annually until 2026. Companies are investing in advanced materials and innovative designs. These advancements aim for higher load capacities and reduced friction.

New materials like ceramics and composites are emerging. They offer remarkable resistance to high temperatures and corrosion. This shift could lead to a longer lifespan for bearings, especially in harsh environments. However, the cost of these advanced materials remains a concern. While they promise better performance, the investment might not always justify the benefit.

Engineering processes are also evolving. Additive manufacturing is beginning to play a significant role. This technology allows for more intricate designs and customizations. However, there are challenges with quality control in production. Ensuring consistent performance across batches can be complex. As the industry progresses, these aspects require careful consideration and adjustment.