What is the Best Alloy Powder Grader for Your Needs?

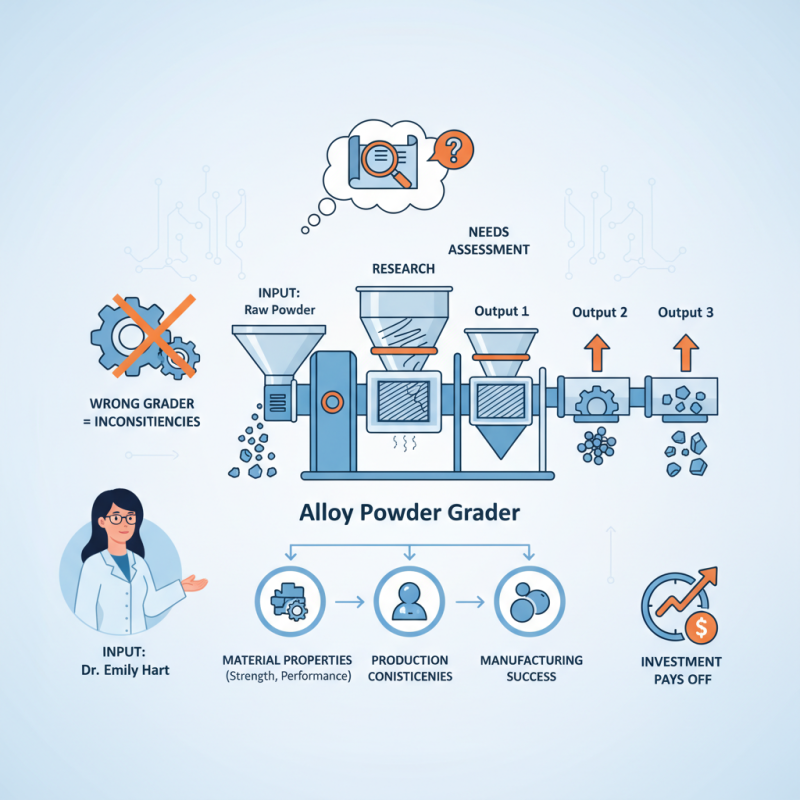

In the world of metal additives, selecting the right Alloy Powder Grader is crucial. Industry expert Dr. Emily Hart, a leading metallurgist, emphasizes, "The precision of your grading affects the entire manufacturing process." This statement underscores the importance of identifying your specific needs.

An Alloy Powder Grader can significantly impact material properties, affecting strength and performance. Opting for the wrong grader may lead to production inconsistencies. Each project requires its own unique specifications. Yet, many overlook this vital distinction, often settling for a generalized solution.

Investing time in research can pay off. Understanding your application is key. However, navigating the options can be overwhelming. Each Alloy Powder Grader presents different features and capabilities. Choices must align with production goals. Mistakes in this area can lead to costly delays. Careful consideration is essential. After all, a small oversight can ripple through the entire project.

Understanding Alloy Powder Grading: Key Concepts and Importance

Understanding alloy powder grading is essential in various industries, particularly in additive manufacturing and metallurgy. The right grade can significantly impact product quality and performance. A recent industry report highlighted that 40% of defects in 3D-printed components could be traced back to inappropriate powder grading.

Alloy powder grading involves assessing particle size, shape, and distribution. Ideally, powders should feature uniformity for optimal results. For example, a well-graded powder can enhance flowability, reducing processing issues. Data indicates that a 10% improvement in powder flow can lead to up to a 25% increase in production efficiency.

However, not all materials perform equally. Some alloys may exhibit poor results despite having ideal grading parameters. Variability in raw materials can produce unexpected outcomes. Companies often overlook these discrepancies, leading to costly mistakes. Regular testing and monitoring are crucial. Without them, manufacturers may find themselves facing reduced profitability and increased waste. It's a complex challenge that requires attention and innovation.

Types of Alloy Powder Graders: A Comparative Overview

When selecting an alloy powder grader, it’s essential to understand the various types available. Each type serves a specific purpose and offers unique advantages. For instance, some graders focus on particle size distribution, while others prioritize shape and density. Knowing your requirements can help you choose wisely.

Many alloy powder graders utilize advanced technologies. Laser diffraction and image analysis are common techniques. They provide accurate results but can be high-maintenance. Simple mechanical screens, on the other hand, may lack precision but are more user-friendly. This option is often overlooked.

Tip: Always consider ease of use. A complicated grader might slow down production.

Another factor to reflect on is the versatility of the grader. Some models adapt to different powder types easily. Others may be limited. Think about the future needs of your operations.

Tip: If possible, choose a model that can handle multiple materials. This could save costs in the long run.

Ultimately, your choice should align with your specific needs. Balancing precision with user-friendliness can be tricky. It's crucial to evaluate what aspects matter most to your operations.

Factors to Consider When Choosing an Alloy Powder Grader

Selecting the right alloy powder grader can significantly influence your production quality. It's vital to evaluate several factors. Firstly, consider the particle size distribution that the grader can achieve. Research indicates that finer powders yield better mechanical properties. An optimal particle size range is often between 10 to 30 microns. Graders achieving this can enhance compaction and decrease porosity in the end product.

Material compatibility is another crucial element. Different alloys require specific grading techniques. For instance, stainless steel powders differ from aluminum in behavior. A report from the International Journal of Powder Metallurgy highlights that the right grading can improve material efficiency by up to 25%. Therefore, understanding the alloy composition and required application is essential.

Lastly, assess the ease of cleaning and maintenance. Graders should allow for quick changes in production lines. Downtime can lead to significant losses. A case study showed that companies prioritizing maintenance reduced downtime by 30%. This efficiency directly impacts overall productivity. Be mindful of your selection, as even small oversights can lead to major setbacks.

Top Brands and Models of Alloy Powder Graders in the Market

In the quest for the best alloy powder grader, several top models climb to the forefront. Each model varies in features and capabilities. A recent industry report noted that precision and speed are critical parameters when choosing a grader. In fact, 75% of manufacturers prioritize accuracy over cost while selecting equipment.

Understanding your specific needs is essential. Some graders offer advanced features, while others focus on reliability and durability. The choice often boils down to volume and type of materials being processed. For example, smaller batch operations may favor more compact models, while large-scale producers might opt for high-throughput machines.

Tips: Assess the size and type of materials you will be grading. This will guide you in selecting an appropriate model. Also, do not overlook the support and maintenance services offered. A reliable service ensures long-term efficiency.

Though performance is a key factor, don’t ignore budget constraints. Striking a balance can be tricky. Some advanced models might promise superior output, but they may also come with higher operational costs. Remember to evaluate your financial capacity against potential benefits.

Applications of Alloy Powder Graders in Various Industries

Alloy powder graders play a crucial role in various industries. They help in assessing the quality of metal powders used in manufacturing. Whether in aerospace or automotive, consistent powder quality is vital. Different applications require specific powder characteristics, such as particle size and flowability.

[Aerospace Image]In the aerospace industry, precision is everything. Alloy powders with tight size distributions ensure better performance. Any deviation can lead to part failure, risking safety. In contrast, the automotive sector might prioritize cost-effectiveness alongside quality. Graders must balance these needs, which can be challenging.

Every industry has unique demands. Graders used in medical devices focus on biocompatibility. However, not every powder may meet these rigorous standards. Finding the right grader requires careful consideration and reflection on specific needs. The quest for the perfect grader isn't always straightforward. Understanding the applications helps manufacturers make informed decisions.